Carry Collaborations

March 2022. Dallas, Texas. The grand opening of Tactile Knife Co’s brand new headquarters. Millions of dollars of precision machines hum from every corner, filling the massive space with sound. Boxes of glistening ribbons of shaved steel. Carryologists pour 12-year-old high proof bourbon into plastic Solo cups. And the single rarest and most coveted products we’ve ever worked on sit within the pockets of the 10 lucky individuals. Our very first knife collaboration. Only 10 were made. A very special micro run to celebrate Tactile Turn’s new HQ.

Ever since that day, collectors have paid eye-wateringly high prices to score their very own. But this collaboration was too good to be carried by so few. So we got together with Tactile Turn and decided to do another run. Not the same thing, no. But a new special edition, in one limited production.

Introducing the Tactile Knife Co x Carryology: Bexar Kōyō.

The Lore of Tactile Turn and the Limited 10

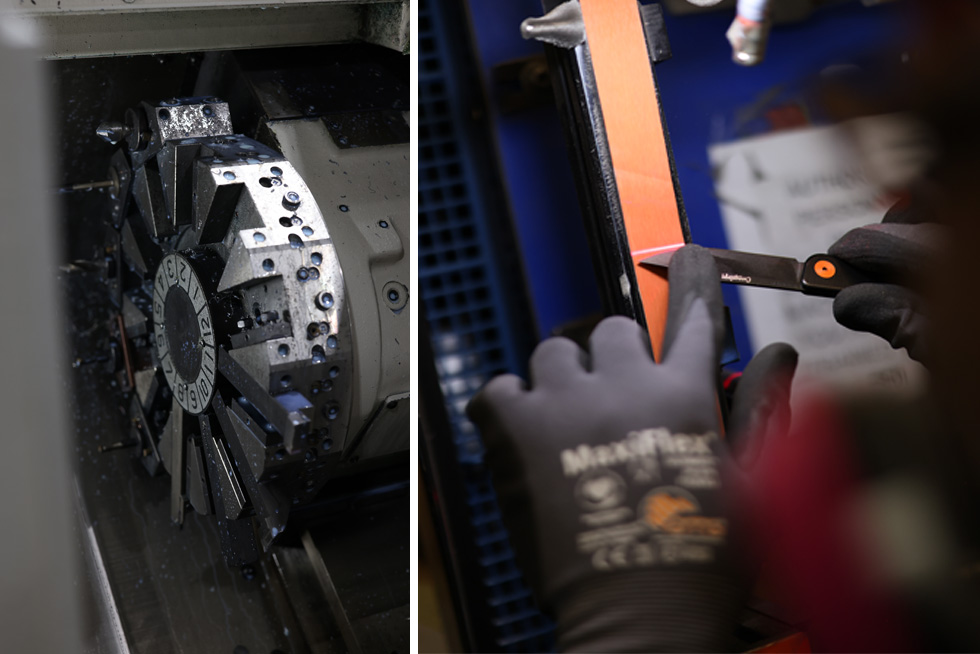

Our long-time friends over at Tactile Turn (founded by the legend Will Hodges) have been turning up some of the finest writing instruments in the world of carry. Every single thing they make is made in the USA by expert craftsmen and machinists within the walls of their state-of-the-art shop in Dallas, Texas. Expanding upon their years of manufacturing prowess and interest in pocket tools, they founded Tactile Knife Co (TKC) under the same roof, focusing on the same extremely tight tolerances, unwavering quality control, and attention to detail.

Now, many small knife brands pop up and disappear into the ether. But TKC has proven itself as one of the top-tier brands in the world in just a matter of years. I and many of our Carryology team and readers have been carrying (and using) TKC products for their EDC and the webstore is constantly sold out just as quickly as they can refresh inventory. The people have spoken. TKC is here to stay.

So when Michael Miller up at TKC dropped me a DM inviting Carryology to co-host their grand opening housewarming event, I said yes of course we wanted to party with them. But Michael had one more fun idea up his sleeve… what if we design and produce 10 custom limited edition Bexar knives for attendees at the party? 100% in. We only had a few weeks to pull it off, but we had a team of badasses ready to go into action. With a lot of work and a little luck, we pulled it off. Much bourbon was poured and all 10 knives were gone in seconds. Epic night and a hazy morning with some award-winning BBQ the next day.

Days, weeks, and months passed by, and the overwhelming love of the Carryology Bexar was obvious. Our community wanted more. So Will, Michael, and I got together to make it happen.

Bexar, the Modern Classic

While the Rockwall is a classic functional design, the favorite of ours is absolutely the Bexar slipjoint. It’s a modern interpretation of the iconic classic. Simple and thin. It’s super lightweight at 1.8oz, and combined with a blade length just under 3″ (overall length 3.84″ when closed), it’s awesome to carry in your pocket, disappearing until you need it. For us, it’s a unique stance on an everyday carry pocket knife. Less tactical. Pure utility. Unique among a sea of carbon copies out there. A pleasure to carry.

Now, let’s make this thing special.

Black Titanium and Steel

First up, the handles must be titanium and the blade must be steel; both must be black. The Bexar is a great platform to start with, as the base model already utilizes Grade 5 titanium on the scales. Grade 5 is essentially the best there is as far as durability and strength. But to add an extra layer of durability and murdered-out awesomeness, we opted for a diamond-like coating (DLC).

Putting on the scientist white lab coat… DLC is typically produced by processes in which high energy precursive carbons are rapidly cooled or quenched on cold surfaces. And as the name implies, this process gives the treated surfaces, just like our knife, diamond-like properties. Think super hard, super strong, and super smooth. Pure awesomeness.

MagnaCut

Titanium is for handles. Steel is for blades. And for this knife, we chose arguably the best steel in the world: CPM MagnaCut. A steel produced by Crucible and hot rolled and distributed by Niagara Specialty Metals.

I only say “arguably” because knife steel nerds could straight up argue about blade steels for days… But MagnaCut is the next breakthrough in blade steel technology in the history of blade steel.

CPM MagnaCut is the perfect balance of all properties one looks for in a steel; high toughness, high wear resistance, and high corrosion resistance.

Many knife steels settle for a trade-off, like more toughness at the expense of wear resistance, but Dr. Larrin Thomas, professional metallurgist and writer of knifesteelnerds.com, employed some clever tricks to make MagnaCut score high marks in all categories.

It has the toughness of CPM-4V (a hard-use steel found on high-end fixed blades) with the stainlessness of CPM-20CV (a tried-and-true premium knife steel used primarily in folders). Thanks to its high wear resistance, it boasts excellent edge retention. As I type this, many brands are switching over to MagnaCut, as it is quite possibly the best all-around blade steel in the world at this moment.

Cerakote

To add a little pop against the all-black-everything appearance, we needed some orange accents. We opted for liquid ceramic polymer coating for both durability and rich saturation. Cerakote is used in several industries for its amazing properties; automotive, sporting, tactical, and many more. After experimenting with a few shades, we found the perfect blaze orange. It would be applied, in-house, to all the hardware screws, the titanium bead on the paracord lanyard, as well as the pivot hardware.

Pivot

Speaking of pivot hardware. Something we really wanted to do on the first ultra-limited run of 10 knives, but could not pull off due to time constraints, was add a custom engraved pivot. A perfect location for a logo lockup. The machinists at TKC discovered that we could engrave our “C” Carryology logo onto the pivot, using lasers. Of course, we loved that. And while we were using the industrial-powered laser, we’d laser engrave the full Carryology script logo onto the blade, just next to the MagnaCut marking.

Titanium + MagnaCut + Lasers = WIN.

Leather Sheath

And finally, there had to be a classy and useful method to carry this sharp black and orange piece of kit. The man himself, Greg Stevens, famous leather worker based out of Utah, joined up with us for the project. Greg selected some thick harness leather from Wickett & Craig, founded in 1867 and located in Pennsylvania. Of course, we went with super dark black and orange waxed thread for contrast. And to add some extra visual and tactile texture, a field of our very own custom Auxikko pattern debossed into the surface of the leather, using extreme pressure and time. Auxikko is a coming together of two distinct inspirations: the ancient Japanese Kikkō pattern based on the nested hexagons of turtle shells. And the modern engineering concept of auxetics – structures or materials that transform under pressure, making for incredible strength and performance. Combine the two and you have tradition and innovation, science and art. A perfect balance.

The Name is Pure Utility

As mentioned, we used the Bexar knife model as a jumping-off point, as developing a knife from the ground up could take months/years of work and cost more than an Aston Martin in development costs. We love the Bexar, but it needed a bit of differentiation to make it fun and unique. A deep dive into ancient mythological weapons, the etymology of modern-day knife styles, and more. Finally, the leather-bound reference books went back on the mahogany bookshelves.

Unanimously we had landed on Kōyō, the Japanese word for “utility”, as we’ve found this collab pocket knife an infinitely useful companion to disappear in our pockets for EDC.

_____

Drop Date

Release Article with purchase link will go live on Carryology.com on:

16th September, 4pm Eastern, New York Time

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews