The Pro Guide to Dyneema® | the Modern-Day Miracle Material

Thank heavens for chemists! Let’s be honest, for most of us, the topic of synthetic fiber science seems both hard to get excited about and impossible to comprehend. Thankfully there is a special breed of person who loves it. So much so they chose to dedicate their lives to researching and discovering new fibers. And thanks to these chemists every few decades we get a breakthrough discovery that changes the game. In the ’40s, the launch of Nylon started a fashion revolution, then helped the Allies win World War 2. After Nylon came Lycra and Kevlar, and now Dyneema® is the newest material to capture the public imagination.

By now you’ve probably noticed Dyneema® popping up more and more in both high-tech outdoors gear and even high fashion. What you might not know is that Dyneema® has actually been around since the ’90s, helping to stop bullets, moor oil rigs and repair human joints. Given the amount of mystery surrounding this latest miracle material, we thought it was about time we gave you the full rundown.

What is Dyneema®?

In its most simple form, Dyneema is simply just a tiny synthetic fiber. What makes this little guy a modern-day miracle is that it happens to possess some incredible qualities. The most famous trait is its amazing strength-to-weight ratio. But it also boasts a long list of other beneficial characteristics that have made it useful across a huge range of applications.

Unlike natural fibers that you might find in nature, like wool or cotton, synthetic fibers are found in the lab. This particular fiber was discovered by the Dutch company DSM. They also gave it its proprietary name “Dyneema®” and hold the exclusive rights to manufacture it. Along with Spectra, Dyneema® is one of the two predominant types of fiber known as an ultra-high-molecular-weight polyethylene fiber, or UHMwPE. While Dyneema® has only been around since about the ’90s, the story of how it got here goes back over 50 years.

Before DSM discovered the fiber, UHMwPE was already well renowned in its solid plastic form. Due to its amazing strength and high impact strength, it had become the material of choice for spine implants and hip replacements as early as the 1960s. Around the same time, DSM decided to establish a new research department looking into the new field of polymer technologies. One day in 1964 the head of the new department, Dr. Albert Pennings, happened to start stirring one of the polyethylene solutions he’d been working on. While stirring, Dr. Pennings began to notice crystals forming whisps around the stirring rods. And by complete chance, these whisps turned out to be incredibly strong.

Like all good things, the journey to turn the discovery into what we know today as Dyneema® took time. Three decades, in fact. Aside from corporate politics and funding issues, there was a major hurdle in figuring out how to produce these fibers on a commercial level.

To begin with, DSM didn’t have a background in producing fibers, otherwise known as spinning. To make matters worse, Dyneema® couldn’t be produced through any existing spinning methods. So 14 years after the initial discovery DSM decided to set up another new research team. This one tasked with finding a way to produce Pennings’ tiny whisps at a commercial quantity.

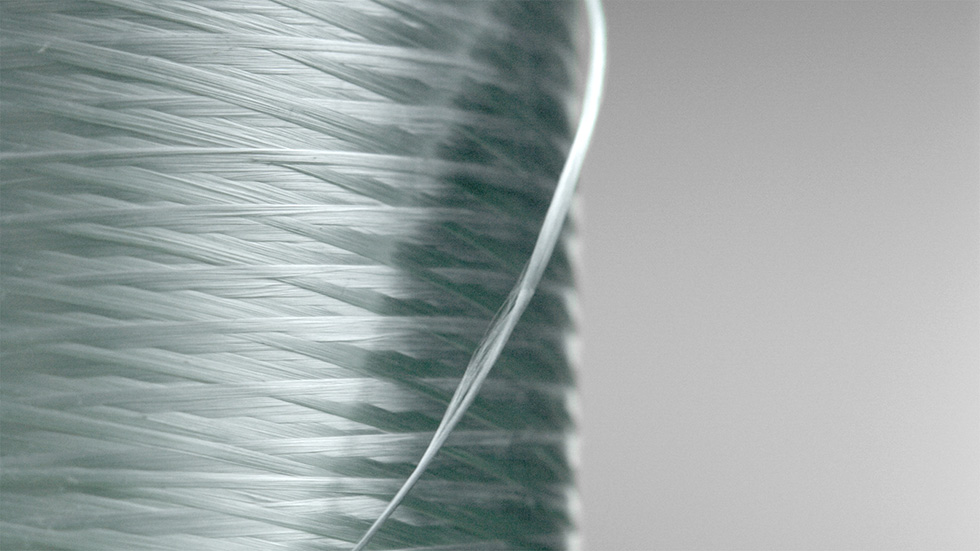

What resulted was another significant discovery, a patented process known today as gel spinning. Here’s the part where things get a little bit technical. In gel spinning, the polymer is first dissolved into a gel state using a solvent. Then it is squished through a device known as a spinneret, turning it into tiny strands. While still in their gel state the strands are then stretched out, which is where the magic happens. The stretching results in near-perfectly aligned molecules. The standard analogy is that molecules transform from a mess of spaghetti into a packet of neatly aligned dried spaghetti. This combination of super-strong UHMwPE polymers formed using the unique gel spinning process is the core of what makes Dyneema® unique. Jump forward another 12 years to 1990, and DSM had successfully established Dyneema® as the strongest and most durable lightweight commercial fiber in the world.

What’s so great about Dyneema?

You might be thinking, if Dyneema® was around in the ’90s why am I only hearing about it now? Unfortunately for the outdoor enthusiasts, DSM was going BIG. It’s because of the raw strength-to-weight advantage of Dyneema® over materials like steel that the fiber was first snapped up by big industry. You see, Dyneema® is 15 times stronger than steel and 40% stronger than its main rival Kevlar. This also gives it a crazy high tear strength, around five times higher than a like-for-like fabric made using HT-Nylon. Dyneema® is also self-lubricating, which when combined with its strength gives it amazing abrasion resistance.

To launch Dyneema® into the market, DSM decided to focus on pushing these properties to the extreme. Some of the first practical uses included body armor that could stop bullets from a Kalashnikov and mooring lines that broke the machines meant to test them. But it’s not all about strength. What’s particularly unique about Dyneema® is the combination of strength with softness and flexibility (it even floats on water).

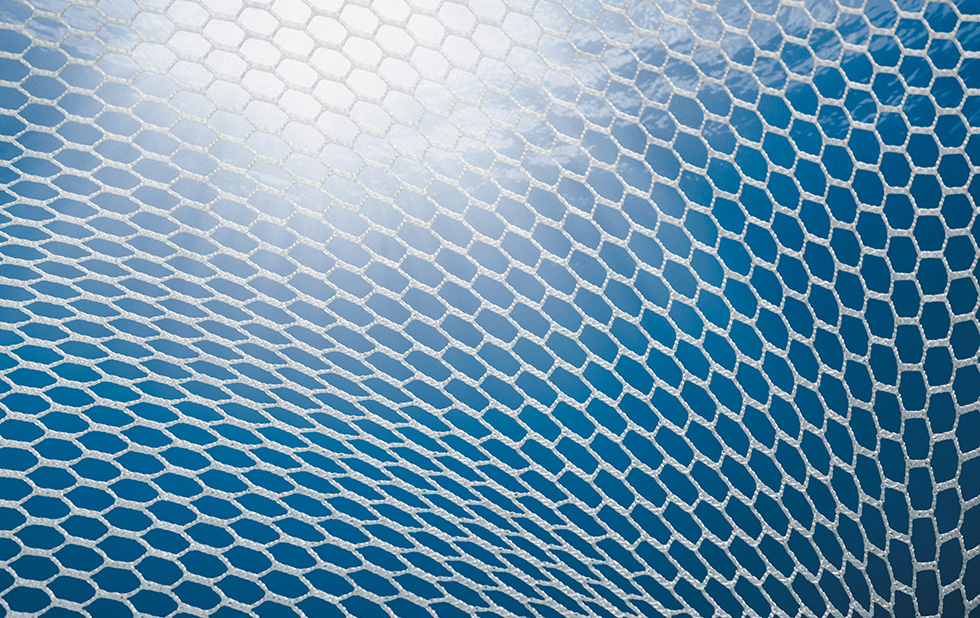

These days Dyneema® has worked its way into all aspects of life wherever strength is needed. From cut-resistant gloves to safer winch ropes and lighter trawler nets. If all that is still not enough to impress you, in 2008 Dyneema® was chosen as the fiber to weave a 30km rope that was used in an experiment to tether a satellite to the earth. And if all of that still isn’t enough? It’s impossible to not be amazed by Luke Aikins’ 2016 parachute-less jump from a plane. After falling 25,000 feet Luke was traveling at 120mph when he was safely caught by a giant net made with Dyneema®.

Dyneema® vs Spectra

Though similar, Dyneema® is not the same as Spectra. There are performance differences in the specific fiber properties (product grades) and manufacturing process. Dyneema® has a manufacturing facility in Greenville, North Carolina for the fiber and all fabrics are developed in Mesa, Arizona. Spectra is also a proprietary UHMwPE fiber, in this case, developed by the US company Honeywell.

Dyneema®’s first steps in the carry world

Looking at the latest Dyneema® developments, it’s impressive to see how far the fiber has evolved. Compared with the slick finish of the Team DSM cycling apparel, the early days of Dyneema® in the outdoor industry were a lot more rugged. Unlike a lot of high-tech developments, it wasn’t the big brands that first started dabbling with Dyneema®, but small ultralight brands and experimental makers.

As early applications of Dyneema® were all about brute strength, production of the fiber was fairly simplistic. The nets and ropes being made for fishing trawlers and oil rig moorings were a long way from fabric and a very long way from cycling apparel. But around about the same time high-end sailmakers had developed a new composite fabric technology that incorporated high-performance fibers. The new sailcloth was made by sandwiching networks of ultra-strong fibers between layers of lightweight fabrics. Similar to plywood, the combination of layers created a fabric that was stronger than the sum of its parts, as well as being waterproof and incredibly lightweight. The new technology made its America’s Cup debut in 1992, becoming known in the industry as Cuben Fiber. This proved to be the vital link that would open Dyneema® to the outdoor market.

Through Cuben Fiber ultralight makers, such as Bill Fornshell of Ultra-Lite Skunk Works and Mountain Laurel Designs, were able to tap into Dyneema®’s potential for making incredibly lightweight packs. For the era, the first packs they created seemed from another planet, both in terms of weight and look. As light as a golf ball, and always a semi-transparent off-white fabric that looked almost like a throwaway plastic bag. Cuben Fiber also provided a supply chain to source small quantities of Dyneema®, which spawned a wave of makers. Over the following years, the designs progressed through brands like Zpacks, Six Moon Designs, and Hyperlite Mountain Gear. It wasn’t long until DSM saw the potential of this new market and in 2015 they purchased the company making Cuben Fiber.

New Frontiers for Dyneema®

Since the acquisition, Dyneema® has been busy working with brands to merge these two technologies. And in that short time, they’ve created a pretty impressive range of bag and apparel materials offering performance properties such as enhanced strength or reduced weight. On the carry front, brands like SDR Traveller are incorporating the high-performance properties of Dyneema® into travel and commuter gear. Their D3 Traveller Duffel uses an incognito Dyneema® composite that’s both strong enough to carry a load of bricks and so lightweight it packs down to the size of a notebook.

Now even luxury brands such as Moncler are getting in on the act. Their 2020 collection was self-described as a merger of skiwear and space suits. It is a functional range that plays up the material’s unique look and exotic appeal. ECCO Leather is bonding a Dyneema® composite fabric to leather to make the thinnest yet strongest leather on the market. Dyneema has also partnered with other fabric mills to develop high-performance fabrics like motorcycle denim and protective cycling jerseys. You can check out a bunch of innovative creations in the Dyneema Project.

Renewable Dyneema®?

Today, with Dyneema® in high demand and in large-scale production, the chemists at DSM have since turned their attention to improving DSM’s environmental impact. Specifically, Dyneema® is aiming to move toward a circular production system for the fiber. In 2019 the company pledged that from 2030, 60% of Dyneema® fiber feedstock would be sourced from bio-based raw materials. The pledge also committed the company to find a way to recycle Dyneema® at end-of-use. So far progress is looking promising on both of these fronts. Last year they made their first major steps honoring that pledge, launching bio-based Dyneema® fiber made from the byproduct of the wood and paper industry through mass balance accounting. By cleverly incorporating a renewable input at the very start of production, the remainder of the process is left unchanged. The result is a bio-based fiber with no loss of performance at all.

Now, to further enhance the impact of their protective products across the value chain, DSM have also helped launch a cross-industry coalition, known as CirculariTeam®.

Additionally, earlier this year DSM announced that small-scale recycling experiments had proven successful. Due to the fact that Dyneema® is often used as a composite, there might be a long way to go before we’ll be recycling any backpacks, but it’s a promising start. And if there’s one thing DSM have proven over the years, it’s that they’re in it for the long haul.

Packs featured in hero image: Best Made Company, Patrol Pack, Hyperlite Mountain Gear Prism

Jacket: C.P Company Metropolis 020

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews