Human Interface: a Guide to Backpack Harness Innovation

Before we had technologically advanced, high-performance gear (that we all geek out over) early humans began with the basic need to carry tools and wares that helped determine our success as a species. Enter the backpack. There are few things that exemplify the evolution of human-centered design better than a backpack because it is so closely tied to our survival as well as our physical bodies throughout our history. The earliest backpack ever discovered was found by the mummified body of the Otzi iceman who lived between 3400 and 3100 BCE. But it is only in the last few centuries with the advent of modern materials and manufacturing methods that backpack innovation has really taken off. While the backpack continues to evolve, as do the items we carry, one thing remains constant: the complexity of the human body. Backpacks have to contend with a multitude of human physical traits that require elegant yet complex design solutions. Mike Pfotenhauer, founder of Osprey, describes a backpack as a “3D kinetic sculpture: it has to move with your body and what’s more complex than the human body?” Let’s take a look at some of these innovations, vis-à-vis the designer’s approach to the challenges of the human interface.

FIT ADJUSTMENTS

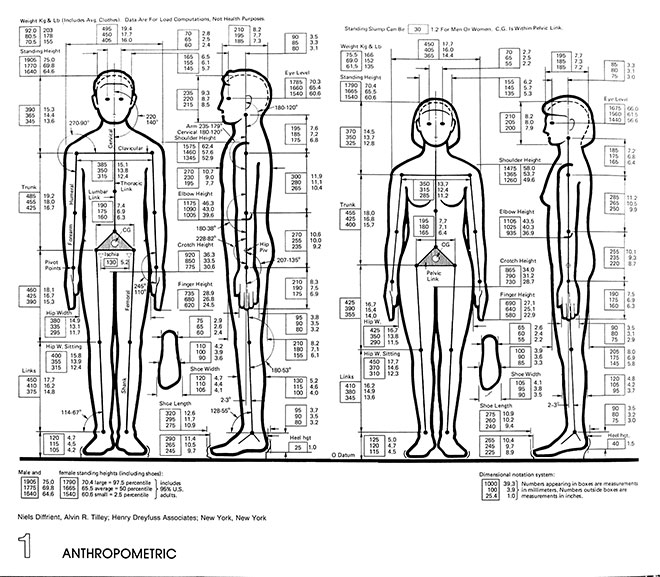

In general terms, shoe size is determined by foot length; for packs, it’s torso length. A properly fitting backpack (with hip belt) is one where the mass of the pack is evenly distributed from the C7 cervical vertebra (the bony part at the base of your neck) down to the iliac crest (top of the hips) where the majority of the weight should sit. But unlike shoes, packs only come in a few sizes, if at all; and torso lengths can vary widely from approximately 13″ to 23″ in length. Over the last 50 years, designers have tackled this problem with a myriad of ways to expand, contract, and lock into place the separation points between the shoulders and hips. Today, torso adjustment methods are often brand-specific, hybridized and given their own clever names. This can make buying and fitting a pack pretty confusing, but here are some of the fundamental examples.

Slide’n’Lock

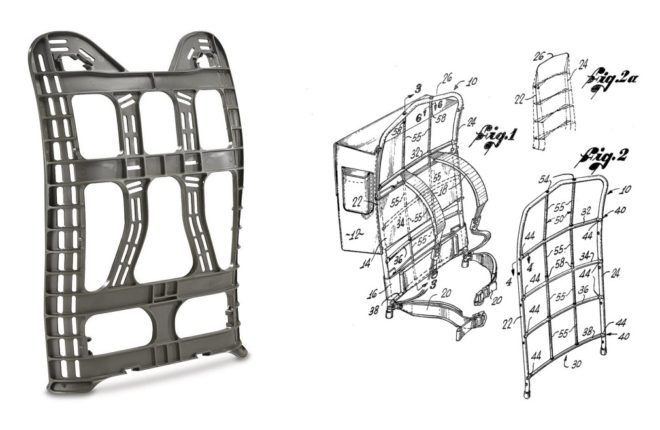

In some of the external frame packs of the ’60s like the JanSport D2, the top horizontal cross bar where the shoulder straps attached could slide up and down the vertical frame and lock into place. The hip belt/lumbar padding could also be shifted up or down on the frame with webbing and ladder locks.

The Alps Mountaineering Red Rock 34, a modern-day external frame pack, has telescoping poles that attach to the hip belt. The ability to make these torso adjustments is a big improvement over the fixed frames of the past, but the trade-off is that there are more mechanical parts that could break.

The Ladder Back

In this system, the shoulder straps are connected together at the neckline and attached to an array of horizontal loops, much like rungs on a ladder.

This system allows for intuitive and quick on-the-go adjustments in the field. As a bonus, the narrow point of attachment between the shoulder straps and the pack body enables a sort of pivoting motion which can improve upper torso mobility.

The downside of this system is the limitations in adjustment range and fine-tuning. Also, the yoke creates extra bulk in the upper back area and “gaps” down the middle of the back that could be uncomfortable to some. This system is kind of old-school nowadays but it still gets the job done.

The Keyhole

This design involves plastic hardware components whereby the top of the shoulder straps are attached to pegs or toggles that slot and lock into “keyholes” on the upper frame.

This design creates a really solid and direct connection between the shoulder straps and the frame which some may prefer, and is probably the easiest and most intuitive to adjust in the field. Some keyhole designs even allow for shoulder width adjustments.

The disadvantage of this system is the limited range of adjustment, usually constrained to only a few slots. Also, the added hardware will scare off any of the ultra-light folks.

The Peel & Stick

In this design, the shoulder straps are attached to a flat sheet that is slotted behind the back panel padding. The sheet attaches to the pack body in a peel-n-stick fashion via hook and loop. The Mystery Ranch Futura yoke being a variation of this.

This design has also been applied to hip belts, enabling hip circumference adjustments. Very fine-tuned adjustments are possible and the design maintains a low, flat profile on the back.

This is definitely the most common method out there right now and for good reason. This is also usually the most difficult to adjust, especially with a fully stuffed pack. It can take some effort to rip apart the Velcro panels and align them just right, but once it’s set you’re good to go.

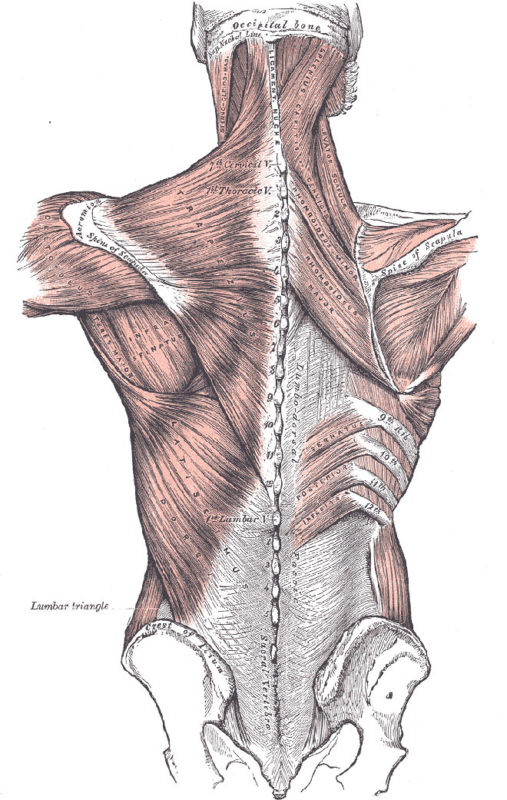

BODY CONTOURING

How did we go from the painful, stiff and rigid knapsacks of the past to the body hugging packs we have today? The solutions may seem obvious now, but it didn’t come quick or easy. Anthropometry, or the scientific study of the physical measurements and proportions of the human body, took several centuries to develop. Ergonomics, or the study of human efficiency, comfort and safety, didn’t become a recognized field of research until World War II as a need to prevent critical failures in human/war-machine interaction. Who knew that a poorly designed control panel could result in more airplane crashes? Like most wartime innovations, these newly applied approaches to the human body, along with advancements in manufacturing and materials, eventually filtered down to the design of everyday products like backpacks. Wayne Gregory, founder of Gregory backpacks said, “you don’t carry a pack, you wear it.” Let’s take a look at how these innovations were applied.

Back Bends

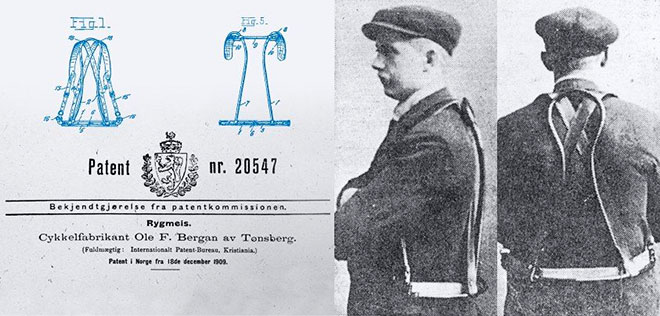

In 1908, Bergans of Norway introduced the first pack frame to use tubular steel instead of wood, and the tubes were bent to follow the shape of his back.

In 1952, Dick and Nena Kelty (of Kelty Backpacks) designed the first external frame pack using welded, contoured aircraft aluminum.

In 1957, Jack Stephenson came out with an aluminum frame that contoured around the hips. It’s interesting to note that around this time period, the same metal bending innovations were taking place in the furniture industry starting with Marcel Breuer’s B3 chair in 1925.

Modern-day advancements in materials include polymer frames as used by the US military, lightweight aluminum wire-frames, and compression molded carbon fiber.

S-curve

Initially, shoulder straps were made of straight, unpadded canvas or leather, which had limitations in comfort, fit and weight distribution (although leather straps had the benefit of being able to naturally shape over the body).

Over time, curvilinear shoulder straps were introduced, starting as a simple arc that later evolved into an S-shaped curve.

The S-curve allows the strap to evenly conform around the neck, upper chest, and sides. This concept was also applied to the hip belt as a U-shaped curve.

Pack designers have developed countless variations in search of the optimal curve, but generally speaking, the more relaxed the curve the wider the range of fit. There are instances where certain curves are more advantageous. For instance, a relaxed, elongated curve is better suited when bulky layers like a down suit are worn, whereas a more articulated curve will keep a pack closer to the body of a trail runner or cyclist.

Women’s Fit

In 1979, Lowe Alpine created the first women’s-specific pack that was engineered to fit the contours of a woman’s body. Women’s-specific fit takes into account the different proportions between a woman’s neck, shoulders, and chest. This results in a slimmer and shorter shoulder strap with a unique S-curve.

Women’s hips are also more conically shaped due to the larger differences between hip and waist circumference. This results in a hip belt that has a deeper U-shape. The shape of the pack body and angle of attachments can also be adjusted for the differences in center of gravity between a man and a woman’s anatomy.

Custom Fit

Packs that pre-date the advent of manufacturing benefitted from the fact that they could be built to fit the person wearing it. There still exists a small group of pack makers like McHale, who offer bespoke, made-to-order packs based on a list of specific body measurements.

Innovations that bridge the gap between mass manufacturing processes and custom tailoring are Osprey’s Bioform4 CM™ and Isoform4 CM™ hip belts. This is a system whereby the hip belt is heat-molded using a specialized oven and while still hot, placed on the wearer’s hips to mold and conform around the body.

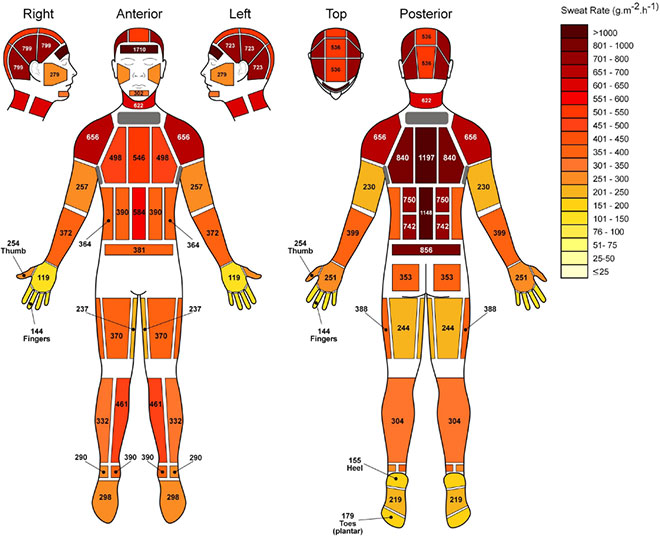

BODY HEAT VENTILATION

Designing a pack that aids in the ventilation of body heat goes beyond just reducing “swamp back” purely for the sake of comfort. A well-ventilated pack can have real performance advantages in terms of reducing energy loss, perceived rate of exertion and a decreased risk of dehydration. Lowering body heat means reducing the need to excessively hydrate, which in turn means carrying less water weight. Also, when the body eventually cools down once it comes to rest (or the sun goes down), a soaking t-shirt can pose a real hypothermia threat. A pack that dissipates body heat will make you safer, more comfortable and more efficient.

The Trampoline

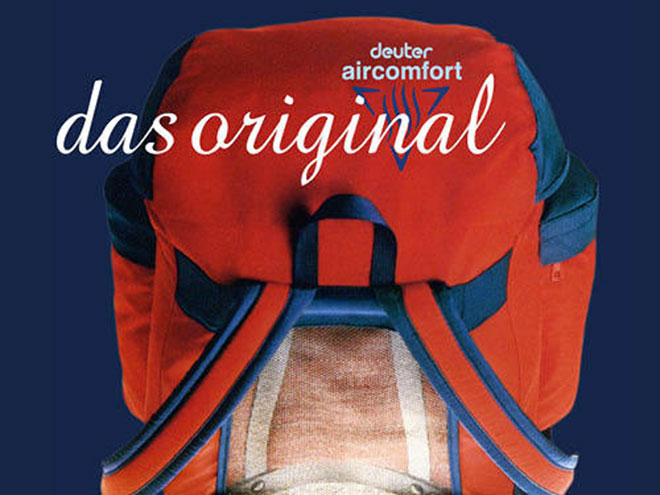

In 1984 Deuter patented the Aircomfort; a mesh back panel held taut by aluminum bars that created a sort of trampoline that “suspended” the surface area of the pack away from the wearer’s back. This design has been widely iterated by just about every pack maker ever since.

Osprey’s AntiGravity system took this concept from the back panel and extended it all the way through to the hip belt in one continuous web. While this design does an excellent job at ventilation, it pushes the mass of the pack away from the center of gravity that runs down the spine. This can result in the pack feeling a bit “disconnected” with the body.

Also, in order to create the trampoline effect, the bars supporting the mesh must arc into the pack body, potentially reducing its usable capacity.

Foam Air Channels

Another common method to ventilate body heat is using compression or injection molded EVA foam.

The molded foam sections are applied to back panels as well as hip belts and shoulder straps. The 3D channels and ridges allow hot air to flow and escape laterally across the panel. If the foam is perforated, it can allow heat to escape through the panel as well. The foam panels are often covered in a stretch air-mesh that further increases surface airflow and comfort.

While it isn’t as breathable as the trampoline, it keeps the mass of the pack closer to the spine. The best designs minimize surface contact while maintaining proper support and comfort. Oh, and they look pretty cool too.

BIOMECHANICS

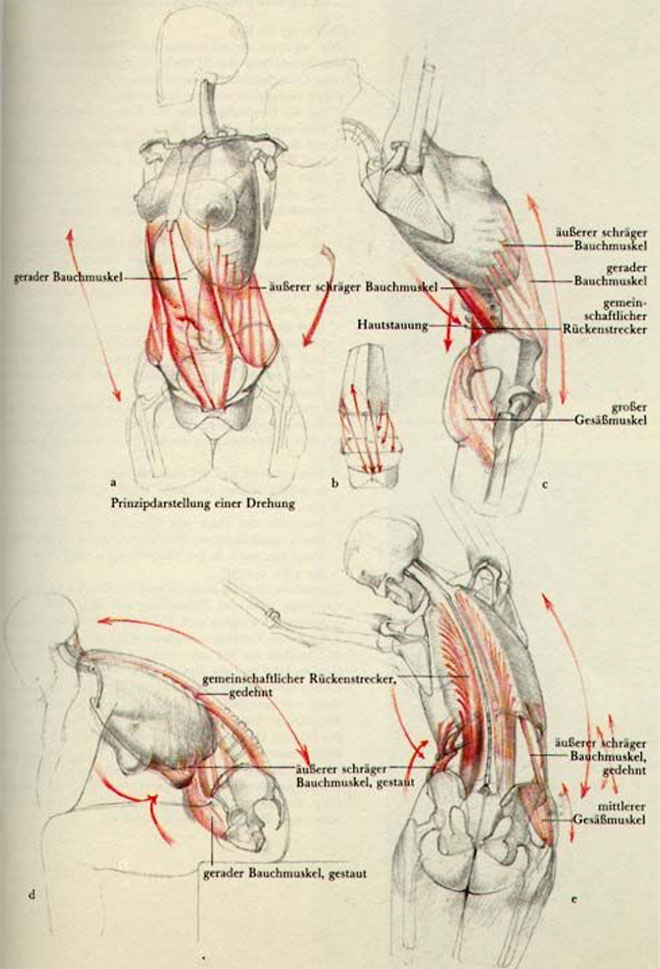

When walking, the hips swivel in a pendulum-like motion. Add bending, reaching, twisting and uneven ground to the mix and the body presents complex ranges of motion on multiple axes. Despite this, the structures of early external frame packs were stiff, inflexible and restricting; not too far from the feeling of strapping a lawn chair to your back. And because the rigid frame was anchored directly to the hips, the weight of the pack was forced to teeter-totter with each step, lagging behind slightly. At best this could lead to a general discomfort and at worst it could lead to a total loss of balance; especially when jumping, moving sideways or taking big, uneven steps. “Active suspension” systems are one way designers have attempted to solve the rigidity/weight-shift problem by adding a degree of flexibility and movement to the frame. The challenge is finding the delicate balance between increased mobility and structural stability.

Hip Mobility

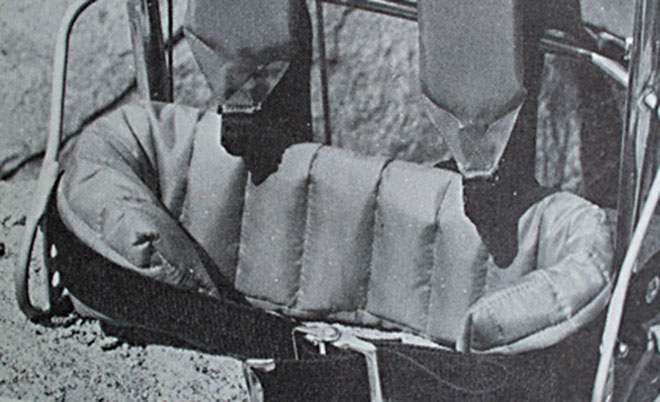

In 1962, A-16 modified Jack Stephenson’s design (aluminum “wings” that wrapped around the wearer’s hips where a padded belt was mounted) by adding swivels where the hip belt was attached. While this design succeeded in freeing up the hips, it did so in the wrong direction. When walking, the hips tilt at the sides; they don’t thrust fore and aft.

In the late ’70s, The North Face’s “Back Magic” frame also attempted to increase hip belt mobility by attaching the belt to the frame via a plastic paddle that flexed and bounced with each step. The problem with this design was that it was almost too freeing.

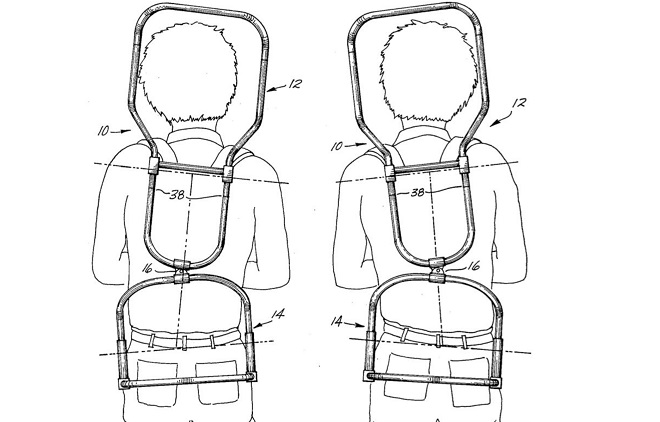

Spinal Mobility

The JanSport Alpine Phantom (1979) was the first external frame pack to incorporate an articulating mechanical hinge that mimicked the side-to-side movement of the spine.

Since then, there have been many active suspension systems that focus on increasing spinal mobility. Black Diamond’s ErgoActiv was designed with a ball joint centered on the hips. On Millet’s Axpel pack, the pivot point was placed in the upper lumbar area. Ergon centered the pivot point between the shoulders.

On the Mammut Trion Spine, there are two pivot points. One is placed between the shoulders and the other on the hips, and they are both connected together with a tensioned fiberglass rod that acts as a motion limiter.

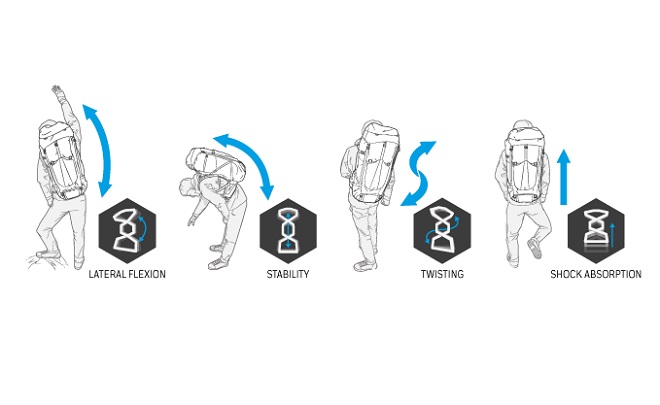

Bergans took a completely different approach, using a typical thin, tubular metal frame, but redefining the entire form to be helix-shaped. The innovative spring-like geometry allows the frame to bend, twist and absorb shock as the body moves without the use of any mechanical joints.

Biomimicry

While packs with active suspensions usually involve the use of pivot points, the Vertepac features a polyamide exo-spine that pivots, twists, bends, compresses and decompresses along its entire length. The spine behaves (and looks) just like a real one and connects the lumbar section of the hip belt to the upper pack frame. Because the bottom of the spine is directly attached to the hip belt, this theoretically frees up restrictions in both spinal and hip movement. The design claims to provide extra support that prevents injury, acting as if the wearer has two spines instead of one. While the exo-spine adds a decent amount of extra weight, Vertepac claims that the ergonomic advantage and reduced energy expenditure makes up for it.

Floating Suspension

When walking, the weight of a pack accelerates and decelerates in a vertical motion with the motion of the hips. On the down-step the weight is slowed and stabilized using the knees and on the up-step, the weight is lifted and accelerated off of the ankles. This cyclical motion can make the pack feel like it’s jerking and lurching with every step. The Lightning Pack (now commercially known as the HoverGlide) claims to reduce the up-and-down jolting by placing the pack on a suspended frame with a bungee attachment that “floats” the weight. This could be very advantageous when walking or running at a steady pace on flat ground, but what happens when leaping from one boulder to another or taking big, downhill steps in sinking snow? The last thing you need is your pack to turn into a Shake Weight.

PACKING IT ALL UP

In many ways, a backpack mirrors our own bodies: its structural frame is much like our bones, its foam and fabric like fat and skin, its straps like tendon and muscle. It bears weight, articulates and breathes. This is by no means inadvertent. A backpack has served as an extension of our bodies since its inception, and the innovations that we’ve discussed were attempts at making the separation between pack and body, the human interface, as seamless as possible. But beyond the physical, there is also the psychological connection behind carrying a pack. While our reasons for carrying packs have evolved greatly throughout our history, from early nomads crossing ice bridges, to students on college campus, to astronauts walking in space, the basic human motivations remain the same. We continue to walk along our path in the pursuit of survival and exploration, carrying what we need for a successful journey.

Many thanks to Jayson Yagi for the above article. Jayson is an industrial designer and pack designer, with former clients including Igloo, Speck, and ReadyRig. He also served as Senior Product Developer at JanSport. Currently, Jayson is a Product Designer at Ruggable. Check out his website here.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews