Designing the Ultimate Winter Expedition Pack

Eric Larsen is one of the most accomplished polar explorers alive. He has skied to both the geographic North Pole and South Pole twice. He was the first person to reach both poles under human power and the summit of Mount Everest in a single calendar year. Most recently he completed a 500 mile unsupported traverse to the North Pole which required him to ski, snowshoe and even swim his way north.

Eric’s expeditions are pushing the boundaries of winter expeditions in a lot of ways, among them bag design. Being a niche sport there’s not a lot of carry gear tailored for these type of expeditions. So a couple of years ago Eric got in touch with Michael Meyer and the design team at Granite Gear to see if they’d be up for designing the ultimate winter expedition pack.

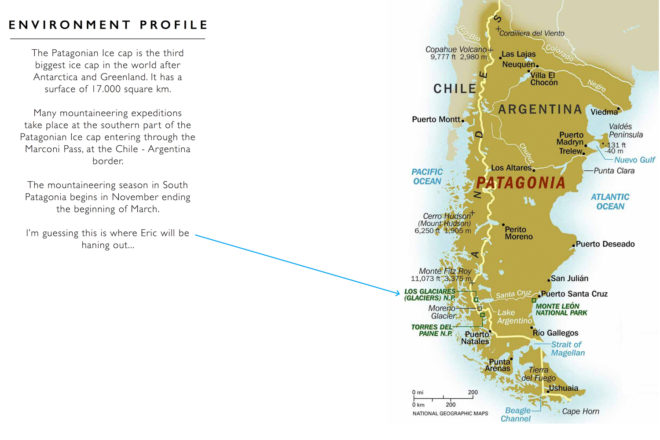

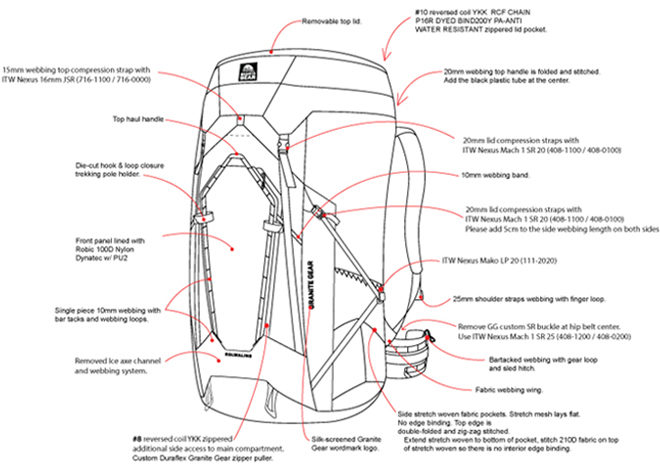

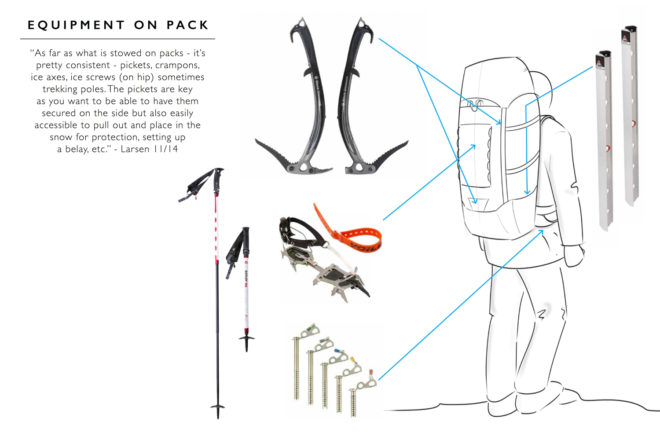

The ‘Rolwaling,’ named after a remote Nepalese valley, had a demanding spec sheet. It needed to be durable, easy to use in extreme temperatures, hold a pile of gear, shed snow, accommodate climbing gear, haul a sled, and work as a mountaineering and summit pack. And Eric wanted to have a prototype ready for product testing on an upcoming Patagonia expedition in a few months.

At this summer’s Outdoor Retailer, surrounded by hundreds of outdoor packs, I talked with Eric and Michael about the process of designing a winter expedition pack unlike anything else on the market. I started with the obvious question, where do you start designing a bag with a spec sheet like that?

The beginning…

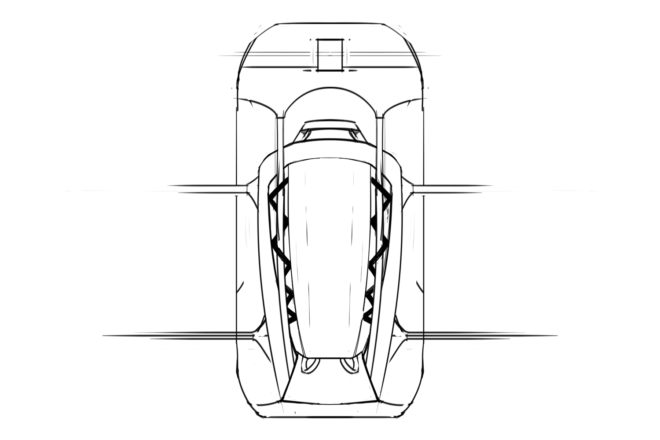

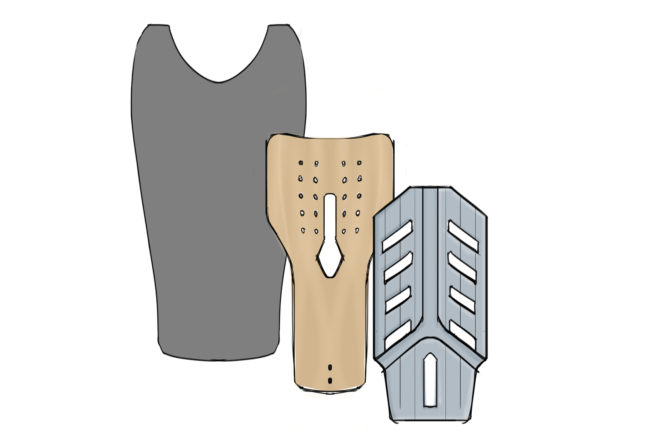

Michael Meyer [MM] – We started with existing winter pack specs and went from there, specifically which frame to use. Do we have a suitable frame in the Granite Gear line or do we need to develop a new one? We explored both avenues but landed on our Maple Core frame sheet. From there we started figuring out how to fit in all of Eric’s carry requirements.

“I started with the obvious question, where do you start designing a bag with a spec sheet like that?”

We’ve used this Maple Core frame sheet in the past on our military line. It’s basically a maple plywood and fiberglass composite that has been vacuum molded. The resulting frame sheet has a 60 lb load rating. And after testing this frame sheet against an identical carbon fiber frame sheet, we found that it was lighter weight with an increased load rating.

Eric Larsen [EL] – The art of expeditions is constantly evolving. I’m always looking back at what bags we used in the past. What were the components that we used then? In this industry there is a tendency of innovation just for innovation so we lose some things in the process. I talked with buddies doing similar expeditions to figure out what worked in the past, these little details that you only notice after a month of continuously wearing a pack.

To start with the Rolwaling, Mike initially sent over a pdf of 10 different sketches of this pack. I was like a kid in a candy shop. I got this pdf in the mail and was like, this is amazing! I had my son on the line, changing diapers, while Mike and I went through each of these designs, looked at each pack, and started talking through what will work and what won’t.

“These little details that you only notice after a month of continuously wearing a pack.”

So with a rough idea in our mind, Mike frankensteined a pack together. And this is where the guys at Granite Gear are so good, they can take my crazy list of sketches and features and translate that into a functional bag. But not just a one-off bag. On Granite Gear’s end it would have been easy to just say here’s the pack, have fun with it out there. But we decided early on to really let this bag evolve on its own. Granite Gear committed to continuous iterations of the Rolwaling and I commit to a couple years of product testing.

MM – The development of this bag began back in November 2014 with the actual design work happening in the Summer of 2015. Today we’re not 100% done with this bag, though I think we’re about one more iteration from putting this thing to bed.

Dig into the details

EL – It’s all about the little details. This is the name of the game when your margins are so small on these expeditions. The back of the Rolwaling has no mesh so that it can shed snow. It’s designed to have good ventilation because we were wearing lots of clothes that can’t get soaked with sweat in these arctic conditions.

MM – The back panel has this dual density foam which is compression molded and then laminated with stretch woven fabric laminated over the dual density foam and then compression molded together. It’s got specific ventilation channels similar to the Lutsen Series Pack. This back panel then translates to the frame itself. It’s a 75L pack with a 60 lb load rating that weighs sub 5 lbs.

EL – But even with this volume the Rolwaling is a short pack. You see a lot of these new packs that are like two stories tall. That’s no good when you’ve got a helmet on, on the side of a cliff, and trying to look up.

The other thing that really stands out for me is how Mike was able to pack down some webbing into the hip belt. Typically when you’re pulling a sled that weighs 100+ lbs it’s pulled off the back of a pack. This is inefficient because it throws off your center of gravity. So with the Rolwaling we designed it to attach to the hip belt.

MM – It’s a simple but effective mechanism. Basically we designed the Rolwaling with a special loop with reinforcement into the waist belt. A sled would then just be clipped into the belt with a carabiner or rope.

“You see a lot of these new packs that are like two stories tall. That’s no good when you’ve got a helmet on, on the side of a cliff, and trying to look up.”

EL – Back in 2015 I went on an expedition to the remote Rolwaling valley in Nepal. At that time it struck me how many things were dialed in with this pack. We were doing these huge hauls up to 17,000 feet with 70 lbs of gear in the Rolwaling. On summit days we were using the brain of the pack [the removable top part] as a summit pack. The frame sheet was small enough so that it didn’t get in the way of a helmet. It was such a functional pack.

The trickle down effect…

I remember later telling Mike, this pack is so good, you gotta sell it. Obviously that was never the motivation for designing the Rolwaling but all of a sudden I’ve got some friends asking for the same pack.

MM – Yeah, this definitely got us thinking. Not only are we satisfying Eric’s needs for a perfect winter pack, but we found ourselves in a position where we could do a small run of this pack in the future. The Rolwaling has also become a brand driving piece for Granite Gear. Both as a bag that highlights our collective design experience and a way to innovate on our consumer line.

EL – When developing some of these pinnacle pieces a lot of the tech and design insights trickles down into the consumer lines. The durability, access and simplicity that went into the design of the Rolwaling translate very well.

“The Rolwaling has also become a brand driving piece for Granite Gear. Both as a bag that highlights our collective design experience and a way to innovate on our consumer line.”

MM – A big demographic of Granite Gear’s customers are thru hikers who share a very similar mentality in regards to bag design. So yeah, the work that went into the Rolwaling was really company wide innovation.

EL – But it’s a two-way street, and that’s the beauty of it. We based all these innovations on the existing Maple Core Frame Sheet. A lot of these consumer level designs are being translated up to us at the expedition level. Granite Gear’s line is so solid that we can take the skeleton of an off-the-shelf pack and build this epic winter expedition pack on top of it. And really, when you look at the Rolwaling, it doesn’t look a whole lot different than other packs in Granite Gear’s line. I think that’s a strong testament to Granite Gear’s bags.

Images credit of Eric Larsen, and the Granite Gear Design Team (Michael Meyer, David Eisenberg, Andrew Ford, and Ben Landry)

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews