Specialist Carry | Creating the Gordon & MacPhail Whisky Trunk

There are really only two key technical issues that concern us when sitting down to design a functional travel trunk. The first is pretty obvious, and unfortunately, there’s no getting around it. Weight. Even in relatively small doses, the combination of wood, leather, brass, waxed cotton, and gold – the luxurious materials we use to actually construct a trunk in our workshop – always adds up. This is of course only compounded by the addition of contents. The second is related, if a little more obscure. But is, if anything, even more difficult to manage. Something we’ve come to refer to over the years as ‘Trunk Blindness’.

Those afflicted become seized by a sort of irrational hysteria. Caused, we think, by the overwhelming romance and nostalgia surrounding travel trunks. In its grip, the imagination runs amok. Wildly optimistic ideas for contents and features spin out of control, and that most basic of carry equations is forgotten: the bigger the contents, the bigger the luggage. (During one particularly extreme case we received two full pallets of proposed contents from a client, destined for a ‘portable’ trunk, required to be no larger than a good-sized camping pack.) There is, I should say, no known cure. Luckily, it can be treated with design.

Fortunately, no one involved in this commission – developed in collaboration with Glasgow’s Pod Creative for Elgin’s legendary malt whisky specialists Gordon & MacPhail – suffered from the condition. Nevertheless, the sheer range of whiskies that G&M deals in is itself so imagination-defying, that the scope of required contents was still highly challenging. With glass and liquid in the mix too, and mindful of airline hold-baggage maximum weights, we had to watch our weight even more carefully than usual.

The trunk was envisaged as an evolution of Prestige Director Stephen Rankin’s interactive whisky tasting sessions. Built to house and transport the tools and liquids he needs to theatrically communicate the many subtle aromas and flavor profiles to audiences around the world. It needed to be large and sturdy enough to transport all of his apparatus securely; dramatic, detailed, and playful enough to captivate participants. Stephen is a man who spends a lot of his time on the road though – often solo – spreading the gospel of single malt, so genuine portability was rarely far from our minds. It’s a gospel he knows better than most. His grandfather (George Urquhart) was a pioneer, a spirited innovator. Laying down casks, bottling, and championing single malt (that is to say, unblended whisky from a single distillery) when most others were promoting cheaper, younger blends. Indeed, few have done more to foster the vibrant whisky industry we enjoy in Scotland today than his family. Which brings us to perhaps the most precious item the trunk was designed to carry: the brand’s values. A task calling for a little, shall we say, Highland flair.

As we always try to do, we worked with Stephen from an early pre-concept stage, even sitting in on a tasting session to better understand his character and process: when and how he uses each piece of kit. Here we quickly discovered that the digital, visual, and sensory are all key components of the experience. And that like any great showman, the reveal is a crucial part of the performance. Noted.

Where we finally landed on contents, when the range of items had been distilled to the essentials, was still a pretty extravagant list: Six glass bottles of spirit, one decanting funnel, six Glencairn nosing glasses, one crystal water jug, three glass water pipettes, 40 vials of aromatic oils, four hermetically sealed glass sample jars, 100 aroma testing cards, one journal, one iPad, four interchangeable A4 presentation cards and, perhaps most difficult of all, six samples of charred and unsealed barrel stave (showcasing the differing levels of smoky aroma with a light, medium and heavy burn, in both American oak/bourbon, and European oak/sherry casks.) A challenging ask, certainly for a handcrafted portable encasement.

A word here on process. Ours is predominantly a woodworking workshop, where we design and make one-off and small-batch sculptural case goods, objets, and furniture, in solid hardwoods and leathers. As such we generally do not – as Vuitton, Goyard, and Globe-Trotter often do with their suitcases and larger trunks – construct our pieces from vulcanized fibreboard or resin-impregnated canvas. Instead, we choose to use poplar: a light, rigid timber. Because of this, we do sacrifice a little in weight and wall thickness. But we believe it’s worth it in the name of precision, build quality, feel, and functionality.

For this trunk we used a combination of 4, 6, and 9mm poplar for the construction of the drawers and the main carcass. Grafting in strips of solid oak – which is much harder – along all exposed edges, and at fixing points, for durability. Where we could, we stripped weight from this rigid carcass by cutting away extraneous material. Such as in the shelving layers between each drawer housing, and in its hidden outside faces.

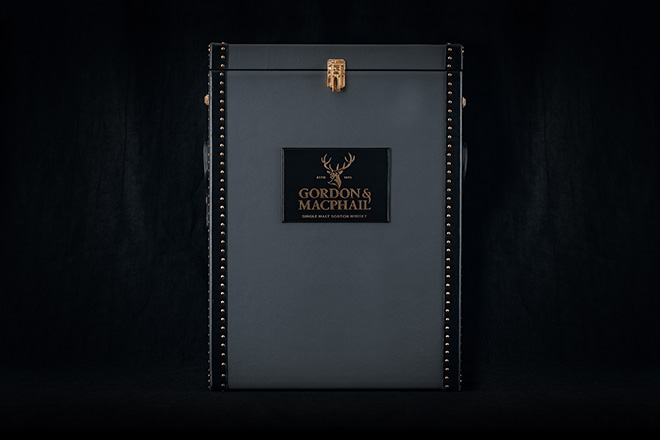

The leather we used to wrap the carcass exterior and interior, and the drawers – each of which is lined with our own design of friction-fit HD foam fitment, to both protect and present the contents – was Scottish: split down from a standard 1.5 to nearer 0.7mm to shave precious grams. Even at this thickness, it’s durable, luxurious, fire-resistant, and easy to maintain. It’s local too, which is always a bonus. For touchpoints, like the protective edging, D-handles, and logo patches, we instead chose a veg-tan bridle, laminated for thickness and saddle stitched by hand. Because of its tactility, thickness, and the clean way it takes a de-boss. (To save a few more precious millimeters, the inner-lid logo patch was actually flush-fitted into the panel work.)

Hardware and fittings are, like the bridle, Italian. Solid brass, gold plated to prevent tarnish (and for some of that aforementioned flair). Here again, our methods differ from traditional malletier (trunkmakers) in that we’ve actually re-bored and screwed or bolted on the handles, catches, and hinges – rather than nailing – as we believe this creates a much more reliable fixing. Though we do tack on the edge protection in the traditional hand-hammered style. (Because, frankly, the chance to use a detail this beautiful is just too good to miss.)

Of all the contents, housing the charred-oak barrel stave samples presented a particular challenge. Burned timber like this is essentially charcoal: filthy, and nearly impossible to handle without marking. The surfaces couldn’t be sealed though, as this would eliminate the aroma profiles. What we needed was to be able to repeatedly remove and interact closely with the samples, without actually touching them. The solution we developed was a set of three superlight individual poplar boxes, each containing a pair of stave samples cut thinly, and fitted very close to the lid of the box. This allowed participants to lift the charred oak close to their noses and open the boxes without physically handling the black stuff, adding to the interactive theater (and in fact even helping to retain the aromas).

The great irony in all this, of course, is that like the little sample boxes, the travel trunk itself had to be housed inside its own rugged encasement in transit. It is, after all, designed to be transported through airports the world over – doubtless to be roughly treated by baggage handlers, ferrymen, porters, and taxi drivers from Tiree to Tokyo – without being damaged in the process. And herein lies another significant design consideration. Protection.

For something as precious and heavy as this (where hold baggage maximum weight constraints, waterproofing, and good maneuverability are paramount) a standard Penn Elcom style flight case – even in the lighter-weight polypropylene FLight Panel™ version – was out of the question. They’re just too cumbersome, and the wheels are of frustratingly poor quality. (And the last thing we want is a Master of the Quaich arriving in a bad mood!) A customized hard-shell suitcase, like a Rimowa for instance, could potentially have been used. But the proportions of suitcases have not been designed with bulky, angular contents in mind. They don’t offer quite enough crush or impact protection either. Instead, we chose here to outfit a waterproof wheeled case from Peli™ (the European trading name for California’s legendary Pelican™ cases), opting for the brand’s super lightweight Air range.

Like all of their protective cases, the Air range was handsome and well-engineered, with two-stage throwover catches, an extendable handle, and smooth running in-line wheels. Even boasting an automatic purge valve, to keep water and dust out while balancing the air pressure inside. But it was made from their patented HPX™ material: a honeycomb polymer that Peli™ claim is still ‘crushproof’ and ‘rebounds without breaking’ but offers a 40% weight reduction from their core range. (The specific 1637 Air model we used weighed in at around 7.5kg including foam.)

Unlike flight cases, however – which can be made to order in any dimensions – the sizes are standard and fixed. And whilst the range is fairly broad, towards the bigger end we found the depths to be a bit of a stumbling block. (With even the largest struggling to meet our 350mm needs.) Tracking down and taking note of this crucial dimension, then, was something we were careful to do before even beginning to sketch out concepts. A factor nearly as critical in the design of this travel trunk, in fact…as checking for symptoms of trunk blindness.

Written by Callum G Robinson, Creative Director, Method Studio & Method Trunk Works, Scotland. Check out Method and their Trunk Works on Instagram for more great designs.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews