From Rough Diamond to Polished Design :: Black Diamond JetForce Interview (Part 1)

If you’re hitting the slopes in avalanche territory, having an avalanche airbag backpack goes a long way to providing peace of mind – up to a certain point, that is. There’s no denying that avalanche airbag packs are valuable life-saving tools, but for such important equipment it’s surprising how many limitations they have. Many such packs have traditionally relied on compressed canisters of gas for inflation, which presents a host of problems – from air travel restrictions to once-off use to name a few. Then the Black Diamond JetForce series of avalanche airbag packs blew onto the scene and revolutionized the industry. So when we got the chance to learn first-hand about these packs from Black Diamond, it was an opportunity we weren’t going to miss.

Black Diamond’s Pete Gompert [Mechanical and Electrical Engineer Lead], Derick Noffsinger [Industrial Design/UI design], Nick Rueff [Project Manager/QA Manager] and Jon Coppi [QA] shared their insights on the process that went into creating this game-changing series…

–

Pete: A few years ago I was in between design projects and my boss came to me and asked if I could research how to improve on the current state-of-the-art in airbag technology. We looked at licensing a bunch of canister-based systems and honestly we were kind of underwhelmed. There’s just so many drawbacks with travel and refill and just general drawbacks to those systems. So I started just off the wall brainstorming to figure out what would be better and tried everything from chemical reactions to giant mechanical springs to all sorts of stuff. One day I went over to the IT department, got a little computer fan and a garbage bag and just fired that up. It was slow but it filled a garbage bag in 10 or 15 seconds. So I got online and I found the biggest battery-operated fan I could which was actually from a ducted fan in a remote-control jet. So I bought that and we tried that and were like “Oh my gosh, this really works, we could blow up an airbag in three seconds.” So it kind of went from there. We had some friends build some prototypes, electronics boards and stuff to make it work and then just started building protos from there and one thing led to another and here we are. We’re actually still using basically that same technology, the ducted fan motor that runs at 70,000 rpm and moves a lot of air really fast.

Andy: Yeah, wow. So the pack is now for sale. You have a few configurations…

Pete: Yeah, we’re doing three Black Diamond packs and I think three PIEPS packs and one POC which is a lot the first season but it’s been good. We’re pretty convinced this technology is the future. There are definitely some hard obstacles to overcome in the development, mostly electronics and battery-related. We’re actually certified to run this thing at -30 degrees Celsius which is a really hard place to run a battery but we were able to find some special chemistry, lithium polymer batteries and do a lot of battery management in the software to make that work.

“We’re pretty convinced this technology is the future.”

Andy: So avalanche airbag backpacks have been in Europe for a long time with ABS, they’ve been out there and it wasn’t until the US standards changed that allowed them here that they could explode, that’s my understanding of it in terms of demand.

Nick: I think the adoption in North America was one part fueled by the availability of the canisters, and then more education, more understanding about how the systems work and their availability. Since then the accessibility of canister-based systems has taken off for sure.

Andy: So when you completely change the way these bags work, the standards, government regulations, that sort of thing, how do you get around those?

Nick: With the canister-based system there are some very specific standards that relate just to the canisters themselves, a pressurized vessel, and there are North American standards for those. Since we don’t have a gas canister we don’t have to worry about that. The standard that’s being developed right now is a CEN standard, so that’s European based, and this is the same certification body that we certify all our climbing equipment through as well. So the specific need to have that certification in North America, there is not as much of a need as there is in Europe. In Europe it’s pretty much mandated in order to sell product. This is what we’ve been doing with our climbing hardware for a long time and so this is the same approach that we’ve taken with the pack.

Andy: Excellent. So it’s really your own in-house standards in terms of when you feel this is reliable enough, consistent enough, to start selling in North America and then as the standard fills out in Europe I guess you will probably help influence that and help them understand what sort of equipment this is and what might be right and what might go wrong.

Nick: We’ve been a part of that process for the last couple of years now. So that standard has been in development. It’s a standard that applies to all avalanche air backpacks – and actually packs is even a little bit limiting. There are some people that have more sort of a harness system and things like that. So any avalanche airbag falls into that standard. We have been part of the creation and the development of that standard and a big part of that is with the new technology, making sure that that standard applies to an electrical fan-based system as well as a compressed gas system. The systems do work in fundamentally different ways and so that standard has been developed and created to accommodate both types of systems. It’s a European-based standard and so as it stands today the standard is not a hundred percent finalized yet but we comply to the standard in its current state and it’s fairly far along its path of development. It’s not too far off from being finalized. But of course we always have our own internal specifications and so just like climbing hardware, the standard is a place to start. You have to make sure that you at least meet those requirements, but then of course we have our own in-house requirements that we have to pass as well.

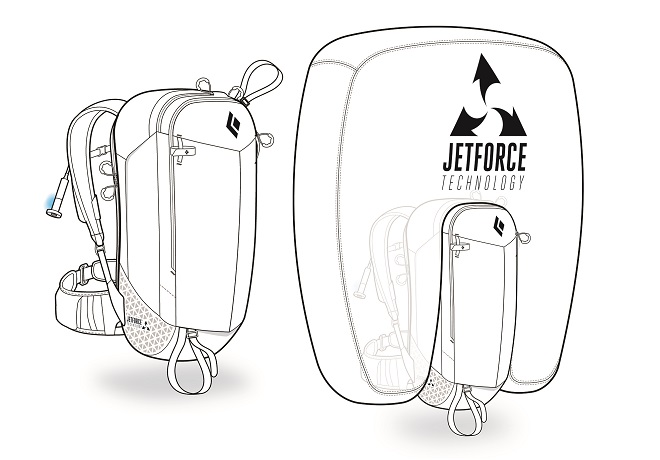

Derick: We have this amazing new technology that we’re bringing to the market and we wanted to make sure that it wasn’t just an airbag pack with crappy functionality. We wanted to make sure that it was – with all our BD packs we build – first and foremost highly functional, no compromise. We started with the idea that we could possibly make this pack with back panel access, making getting in and out of it super quick and easy. So all the JetForce packs are accessible from the back side and like all other Black Diamond ski packs theres a separated avalanche tool pocket in the front where a shovel handle, blade, and probe could store for super quick access in an emergency. What’s really great about this configuration is that you don’t have to take everything out of the pack to charge it. You can leave everything in there for the next mornings tour and still keep it plugged in ready to go.

“We have this amazing new technology that we’re bringing to the market but we wanted to make sure that it wasn’t just an airbag pack first, then a crappy pack second.”

We made the air intake for the system as redundant as possible. On the back is a plastic mono-filiment mesh with a reticulated foam underneath, which is the same type of foam that is used for filtering snow on the intake systems of snowmobiles. The system also sucks air throughout the side quarter panel as well as the inside of the pack through a mesh that divides the airbag compartment from the main cargo compartment.

Andy: Is that sort of tech taken from your AvaLung work on the pack or is that pretty much original for this?

Derick: The air intake and its redundancy was designed specifically for this project. But, what we learned from all our previous work on the AvaLung is that there is air packed snow, and this made us confident thats its possible to suck that air from the snow pack to blow up a balloon. So when you think back about other canister airbags – Why are we bringing air into the backcountry in a canister? There is an abundance of air already there. In this process we made sure it was very redundant so if the back and side panels are blocked it’s still sucking air through the pack through the mesh on the inside, or if everything else was blocked something else was open. We’ve never been able to block it.

Pete: We’ve actually done tests with the pack completely buried and there’s enough air in the snow that the airbag will still inflate.

Nick: And that does carry over a little bit from what we’ve learned with the AvaLung. Even in very high-density snow, snow with a really high water content, there’s still actually a lot of air.

Andy: Because in so many slides you have the friction that melts the snow and starts to condense it right down and so even when you’ve got the massive death cookies, all that, there’s still gaps between those, there’s still air within it.

Nick: For sure, and within the snow itself. We have done a lot of testing where we pack meters of snow around the pack itself and do deployments and it still is able to pull air from the snowpack.

“We have done a lot of testing where we pack meters of snow around the pack itself and do deployments and it still is able to pull air from the snowpack.”

Derick: Back on the subject of functionality and features of the packs – The diagonal ski carry system is actually connected under the airbag balloon compartment and onto the metal frame located at the back edge of the pack. When you really compress down the skis they are supported from the frame making the whole system very stable. Also, we didn’t want anything to accidentally catch on trees so everything is tuckable, such as the loops for an ice axe and the bottom part of the ski carry system, as well as the helmet cover. As for the helmet cover attachment, we had to do something a bit different on these packs. Usually, most of our helmet covers deploy out of a pocket near the top of the pack allowing the user to stow the helmet on the front panel or the top of the pack, but if someone connected the helmet near the top of this bag there is the possibility they would connect it over the airbag opening and we wanted to make sure that there was no chance the airbag would be blocked from deploying. Our solution has the helmet carry deploying from the front/bottom section of the pack allowing the user to store the helmet directly on the back of the pack, or if they are boot packing up a ridge they could store the helmet on the bottom of the pack, allowing their skis to store on the back.

Nick: Yeah, that’s actually a requirement of the certification. You have to be very careful that the pack is designed in such a way that it doesn’t prevent the airbag from coming out. So everything about the pack, the ski carry, the helmet carry, all of that is designed in such a way where you pretty much can’t obstruct anything around the perimeter of the pack because that’s where the balloon has to come out and you have to be able to deploy the pack regardless of whether you’re carrying skis, a helmet or so on.

Pete: Another thing that’s pretty cool about the way Derick designed this is you can still access all your avalanche tools with the airbag deployed which is pretty important when you get caught in a sluff or something when you need to get to that stuff fast.

“…you can still access all your avalanche tools with the airbag deployed…”

Andy: How do you decide on a pack like this between…some guys love carrying their skis A-frame, others are like snowboards, how do you decide when you’re doing something like this as to what you allow for?

Derick: That’s a decision coming from our category manager and his understanding of the market. And overall we all love the quick easy access diagonal ski carry systems provide.

Pete: We had to kind of drive that with function. We’d have loved to be able to make it A-frame, diagonal, and everything but we’ve got a lot of experience with diagonal ski carry, we’ve been making them for a while and we’re pretty good at it and it was just the easiest way to get skis on the pack tight and reliably and still be able to deploy. With an A-frame it’s near impossible to get the airbag out and so it came off the table pretty quick.

Andy: Yeah, that makes sense. And then snowboarding, how do you decide there? So many people are splitboard now anyway but…

Derick: At our heart we’re a ski company and the Halo 28 pack specifically is a ski pack. It will carry a split board but was designed for skis first and foremost. We have other packs in the line and also in the future that will carry a splitboard of course. For instance, the Jetforce Saga 40 will carry a snowboard and in the future we’re making sure to pay attention to that consumer. But yeah, at the heart of all this we started with a pack that will carry skis great, rather than a pack that will carry both just so so.

Pete: And that kind of speaks to the design philosophy on these things too. It’s really easy to make something like this into a Swiss army knife where you have a bazillion features hanging off of it everywhere, an AvaLung for instance. We were very careful to kind of pick the ones we thought we needed in a good ski pack and leave as much off as we could because simplicity speaks as much to function as how many features.

“…simplicity speaks as much to function as how many features…”

Andy: Absolutely, and especially in new tech where you’re not quite sure how this will interact with this and this and this, it makes sense that so much of the design is about stopping people doing certain things that they don’t realize will interfere with the balloon or…

Pete: Yeah, it’s stuff you don’t even realize until you’ve made it that way and then you’re like “Oh we’ve got to change that because that blocks the ice axe holder when the balloon is deployed” or whatever…

Nick: We also had the benefit with distributing across three brands to create some slightly different features between the brands. So the PIEPS packs for example come in a different volume. So the BDs are offered in an 11-liter, 28-liter, 40-liter, whereas the PIEPS are a 24-liter and a 34-liter. We sort of split the difference, and all the PIEPS packs are able to carry snowboards. So some just subtle differences in the features.

“We also had the benefit with distributing across three brands to create some slightly different features between the brands.”

Andy: And then the POC will be smaller capacity, kind of resort based, like slackcountry, sidecountry stuff?

Nick: Correct, exactly. And there’s opportunities to expand on how those brands can offer different features on future packs. The other thing that we get a lot of questions about is when we specify that pack volume we’re talking about the usable space. So that doesn’t take into account the actual airbag balloon. And a lot of other companies will say that they have, you know, 35-liter pack and that’s the overall volume of the pack and then you take up some of that volume with the balloon.

Andy: And I’ve seen how a lot of those companies measure their volume and it’s a guess, it’s often done off CADs.

Derick: We tend to measure our packs based on function, not the little plastic balls the industry uses. For this we sat back and said “Okay, how big should it be for a full-day ski tour?” And that really shaped the sizes of these packs. Although, we did of course “volume ball” these packs to make sure they were correctly labeled. I know we did a lot of volume adjustments based on statements like, “It’s not fitting everything I take up the canyon”, and “My water bottle is not fitting in here”, and “I can’t throw an extra jacket in there”. All these statements really refined our sizing.

Pete: The other thing about the volume of these packs too that Derick’s done a really good job with, he put all the functional components of the airbag itself, the battery and the control box and stuff, is buried way down by your waistbelt and so it carries really nice. There’s not this big clunking weight above, you don’t really even notice it, it’s out of the way.

Derick: Yeah, most of the systems weight is close to the lumbar and feels like natural place, being so close to the users center of gravity. Also, there’s a lot of certifications that make sure the airbag stays attached to the pack in an avalanche. So, there’s a lot of stress tests and pull tests that make sure it does. We designed the frame of this pack to be intertwined between loops from the airbag and loops that are sewn into the mating seam of the back pack. This gives dual functionality to the frame – it helps carry the load as well keeps the airbag attached to the pack securely during an avalanche. When building the packs, this is the last step in the process, to attach the airbag balloon to the pack using the metal frame.

Andy: And the airbags themselves, how different is the tech from auto airbags? Do you need more abrasion resistance because you’re trying to stop snagging?

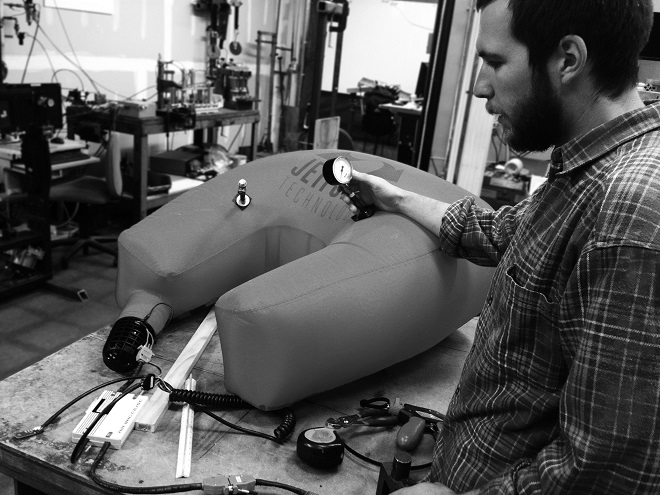

Pete: It’s quite different from an auto airbag. We actually developed that material in-house. It’s a special twisted yarn in there that allows for a lot more stretch and tear resistance. I think we’re the best tear resistance on the market right now. The other thing we do with the airbag is make it bigger, a 200-liter bag just because we have an unlimited supply of air so we can make it as big as we want.

Derick: There’s actually a silicone coating on the exterior of the balloon helping things like branches slide off of it, as well as help the balloon deploy and physically come out of the pack. Also, the woven yarn of the fabric we use is over twisted, like Pete mentioned. This gives the balloon a high mechanical stretch to help with punctures, but still be airtight. We teamed up with Cordura to make this all possible. With the mechanical stretch of the fabric combined with the silicone coating the balloon tests super high for abrasion resistance and puncture resistance, and still allows us to use a light fabric to save weight.

Nick: It needs to remain flexible, it needs to be mostly airtight and it needs to work at very cold temperatures. And oftentimes I think those things run contrary to each other.

Andy: And what do you test down to? Is it like -40 sort of temperatures?

Nick: -30 degrees Celsius is what the standard requires and that’s pretty cold.

Pete: That’s honestly the hardest part of the whole design is getting all these things. All fabrics become really stiff in the cold, so it’s been a trick, and then like I said batteries really don’t like cold so we had to do a lot of work to get the pattern management software and chemistry right.

Andy: And do you have to sort of say “Alright, look, down to -30 degrees Celsius. That’s all we can say we’re sorted for” and then you guys might play with it in Wyoming when Jackson Hole gets to those crazy temps or…

Nick: Yeah, and we have quite a bit of ability in-house. We have a walk-in freezer and a small environmental chamber so we can simulate some very extreme cold. But most of the testing we do has been focused around that -30 degrees Celsius environment.

“…most of the testing we do has been focused around that -30 degrees Celsius environment.”

Pete: And then the worst test, you have to soak the bag in water and then freeze it at -30 degrees Celsius, so that one’s been probably the toughest to pass but we’re doing pretty good right now.

Andy: Is the overall fill rate a little bit slower than in an air canister but then it grows or are you getting almost the same speed?

Nick: It’s basically the same. Both with the canister system and the battery system it has a lot to do with the ambient temperature, for completely different reasons.

Andy: Not just air density…

Nick: Right. But for us, even at cold temperatures there is a requirement in the standard and we are obviously well within that requirement but we are basically equal. The cool thing there is that’s just measuring the initial inflation and for a compressed gas system that’s where it ends. You get that initial inflation and then it seals off and they’re done, whereas ours continues to inflate for another three minutes.

–

Stay tuned for Part 2 where we delve deeper into the workings of the JetForce series…

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews