Ballistic Nylon vs CORDURA: Heavy-Duty Durable Fabrics

Ever wondered what the difference is between Ballistic Nylon and CORDURA®? Industrial designer Janis Lacey sheds some light on this often confusing subject in the guest post below…

When you’re after a super durable textile there are two fabrics that instantly spring to mind: Ballistic Nylon and CORDURA®. These two fabrics have been used for over 50 years on some of the toughest military, outdoor and urban goods around. They are carry industry stalwarts and have been the backbone of many great bags and brands, inspiring endless marketing hyperbole along the way. Amidst all the lofty marketing it can be hard to find the facts, but we’ve waded through the jargon to find the answers to the key questions you need to know when choosing between these two heavy-duty options.

What is a ballistic nylon?

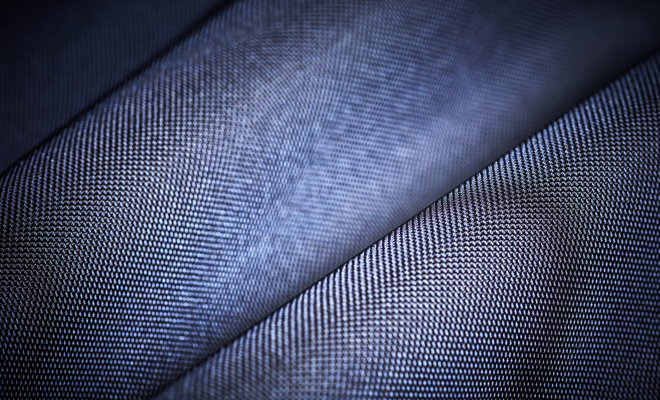

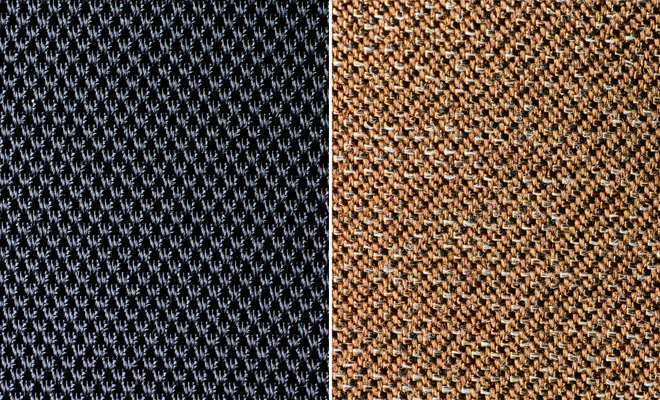

What we know today as Ballistic Nylon is a multifilament high tenacity, 2X2 basket weave nylon fabric, usually made with 1050D or 840D yarns. The name Ballistic goes back to the Vietnam war era when it was used for anti-fragmentation ballistic jackets for the military. Multiple layers of the thick fabric were laminated together to help stop exploding shrapnel and fragmentation. By the late ’70s the military upgraded their armor to lightweight Kevlar® and ceramic plate technology that could stop actual bullets. Then in the ’80s Ballistic Nylon had found its way into the consumer market. At a time when heavy-duty, strong luggage was the flavour of the day, the term ballistic struck a chord with customers and the name stuck. The slick finish, heavy weave and excellent strength still make it a popular choice today, although as a single layer fabric it’s lost most of its actual ballistic credentials.

What is Cordura nylon fabric?

The name CORDURA® has meant many things over many years. Originally a rayon product used in WWII tyres. After the war DuPont developed nylon which became a primary component of tire manufacturing. In the mid-70’s, a process was developed to dye nylon fabric and the CORDURA® name was reborn and applied to the now classic line of nylon fabrics. These days you might notice the CORDURA® brand tag appearing on all sorts of gear; the now INVISTA-owned brand have since developed all sorts of textiles including lightweight and apparel fabrics. But when it comes to bags the fabric most people think of is CORDURA® Classic, air textured, 1000D or 500D plain weave Nylon 6.6. Used in everything from school bags to soldiers’ boots, the now ubiquitous cloth has had a huge influence on the carry world for over 50 years.

What do all those technical terms mean?

All woven fabrics are made up of differing combinations of yarns and weaving methods. Most of the technical jargon is referring to the yarn. Firstly, what’s the fiber? Nylon, polyester, cotton, or a combination of different fibers. CORDURA® is known for using Nylon 6.6 which is a particularly strong type of Nylon.

The “D” in 1000D refers to the denier, probably the most talked about stat. It’s a unit of measurement for the weight of yarn but shouldn’t be used as an indication of strength. How denier is measured is a little convoluted. It is the weight in grams of 9000 meters of yarn. So 1000D would weigh 1000 grams for a 9000-meter length. In turn, 500D would weigh 500 grams.

Then there are all sorts of yarn treatments including the air texturing used on CORDURA®. This is where air is blown over the yarn, making it bulkier and more cotton canvas like in look and feel.

“The “D” in 1000D refers to the denier. It’s a unit of measurement for the weight of yarn but shouldn’t be used as an indication of strength.”

Once you’ve got your head around the yarn, there’s an endless world of weaves, with various designs going back thousands of years. Basket weave and plain weave are two of the more basic methods, with the basket weave ballistic being woven 2 ends over 2 ends. The classic plain weave is 1 over 1 and has a flatter appearance.

What are the key differences between Ballistic Nylon and Cordura?

Ballistic is typically the heavier of the two fabrics and it generally has the superior tensile and tear strength. For reasons unknown, CORDURA® Classic typically has greater abrasion resistance. The generally accepted theory is that the air textured yarn has more bulk, which helps spread the wear. The air texturing also creates a canvas-like look and feel, the downside being that the slight pile does tend to collect dust and lint. In contrast, Ballistic nylon has quite a smooth hand feel and gloss finish.

Looks-wise, CORDURA® is quite casual. It’s synonymous with school bags and hiking packs whereas the polished finish of Ballistic is more suited to business environments. On a practical note, it’s quite hard to find Ballistic Nylon in any color other than black.

“Ballistic is typically the heavier of the two fabrics and generally has the superior tensile and tear strength. CORDURA® Classic typically has greater abrasion resistance.”

One advantage of all CORDURA® fabrics is that they are easily identified. A difficulty when buying Ballistic Nylon gear is that many manufacturers have begun producing lookalikes that vary in quality. If a brand states they are using Ballistic fabric, it’s worth looking a little closer at what the material actually is before you buy.

What should you choose for what scenario?

Also at this point we should make it clear that both these fabrics are super heavy-duty, bordering on overkill for most people’s day-to-day needs. For everyday commuter and outdoor applications either fabric is going to be bombproof. The downside being that they are both quite heavy and may produce a bag of some weight before it’s even packed. And although these heavy-duty fabrics themselves won’t wear out, they can wear out lighter clothing that comes into regular contact with them.

It’s true that both fabrics are the preferred choice in a lot of military applications – but remember that the army is an environment with no room for failure and soldiers carry loads of over 50kg daily. Overall, if I was being sensible I would say the best use for Ballistic is when hauling super heavy loads, and classic CORDURA® is ideal in high wear points like pack bases. But then again, sometimes you want something crazy tough – just because it’s crazy tough. 😉

Imagery courtesy of CORDURA®

Janis Lacey is the founder of Soft Serve Goods design agency.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews