The North Face HQ Visit

My Uber dashes east over the Oakland Bay Bridge, leaving San Francisco behind, and strums down highway 80. I’m en route to Bay Farm Island, Alameda; a leafy suburban enclave one hard right from the gloom of the approaching Oakland, and home to The North Face global headquarters.

My Uber takes a turn off, kicks over a train track, and meanders into the pleasantness of Old Alameda. Its streets are lined with pastel-licked stucco homes and weatherboard Victorians; a canopy of trees droop across the sidewalk.

Minutes later, TNF’s 14-acre Sustainable Campus appears on the horizon, the green hue of San Francisco Bay lapping at its rear.

As I roll in, five cylinder-shaped wind turbines whirl in unison, their rudders buffeted by healthy bay breeze. I disembark and leg it to TNF’s main building (the two neighboring buildings inhabited by other VF Outdoor stable mates: JanSport and lucy). By the curb, an employee juices his electric car at one of the on-campus charging booths, the hose giving off a calm, unwavering hum.

In the foyer, an efficient receptionist takes my name and makes the call. Over my shoulder, an image of a rock climber hangs, one-armed, from a sheer rock face. Behind him is the main entry hall, bisected by TNF’s mantra NEVER STOP EXPLORING.

My host, Matt Paduano arrives soon after. He’s a big human at 6ft 5 and he strides towards me in a long, relaxed gait, neon pink NBs laced to his feet, and extends a hand. Clean-cut and casual in a black zip-up, he looks the part of a design director.

“We’re excited to have you here,” Matt says. His young team read Carryology, and are keen to talk shop. “Shall we?” Matt asks as he shepherds me proudly through the LEED Platinum-badged facility, pointing out the compound’s world-class eco-optimized facilities.

“So we’re totally sustainable,” Matt tells me as we stroll down the hall. “I think we’re even shooting power back into the grid.”

All of the TNF’s 160,000 square foot headquarters’ electricity is generated from a combination of photovoltaic solar panels – slapped on every inch of rooftop and roofed parking areas – and the cluster of aforementioned wind turbines.

“There’s even these solar shades on the windows!” Matt tells me.

“All of the TNF’s 160,000 square foot headquarters’ electricity is generated from a combination of photovoltaic solar panels – slapped on every inch of rooftop and roofed parking areas – and the cluster of aforementioned wind turbines.“

“That’s our community garden,” Matt points to a tuft of green plumage in the bay-facing courtyard – a central meeting place where staff can plant and harvest their own organic vegetables. “The surrounding gardens are all indigenous and take very little water too,” Matt points out.

Then on to their cafeteria, a well-lit U-shaped space stocking locally grown and organic foods; and in the off-hours, it hosts healthy cooking classes for staff (of course it does).

Upstairs, there’s a fitness center and yoga room. Down below, an Astro-turfed outdoor training area – for boot camps and athletics sessions – and a nearby stretch of green which will soon be a rock climbing wall. “It’s really an awesome place to work,” Matt says, smiling.

We re-enter the TNF building and make our way through long-stretching halls and conjoining staircases, each hall leading to different wings, each filled with busy RDD teams (there’s eight in total), cranking away at one of TNF’s many tiers (from Apparel to Summit and everything in-between), every inch of wall pinned with mood boards, fabric swatches, prototypes and grids of hanging bagged components, on route to have a closer look at the RDD facilities and TNF’s cutting-edge toys.

The Materials Library

“This is a new addition,” Matt says. “Our Materials Library”.

The library is as it sounds, with row upon row of fabrics. “We have a librarian too, Laura.” Matt says. “She maintains the library and it’s been a great new resource for us. I can give someone from the materials team a brief and say: ‘This is the material I’m looking for. These are everything it needs to be, the price, the weight, different restrictions, all that’. And they’ll come and find it for us.” And if the material isn’t among the library’s shelves, the materials team develops it. Easy.

“I can give someone from the materials team a brief and say: ‘This is the material I’m looking for. These are everything it needs to be, the price, the weight, different restrictions, all that’. And they’ll come and find it for us.”“

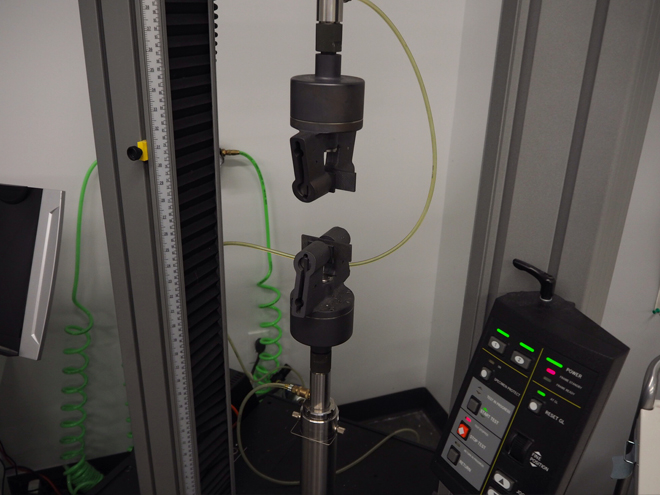

The QA Testing Lab

“All kinds of different cool machines to play around with in here,” Matt says, sweeping a big mitt across the room. Banks of odd-shaped machines skirt the walls, used for abrasion, flame retardance and tension tests. Through a glass pane, a room of industrial washing machines turn over, slopping away at new apparel.

The Color Room

A dark cave-like room, where the color team congregate, stooped over light desks and fabric swatches. “Here’s where we control the color accuracy, do the matching, and make sure there’s a constant hue across the range”, Matt tells me, his face shrouded in semi-blackness.

The Prototype Room

We’re met by the purr of sewing machines; shelves of fabric rolls lump along every wall. A handful of women hunch over their machines and deftly stitch away at panels. “Ling, our in-house pattern-maker and prototyper… So she’ll start with a sketch, make up the pattern, and literally in a day or less, we have something we can start working with.”

“Ling, our in-house pattern-maker and prototyper… So she’ll start with a sketch, make up the pattern, and literally in a day or less, we have something we can start working with.”

“And we have a few other high-end luxuries.” Matt motions to a digital plotter and a digitizer. “So they use these a lot for apparel, but we’ve been using them for the equipment side as well just to kind of help reduce the length of the process.”

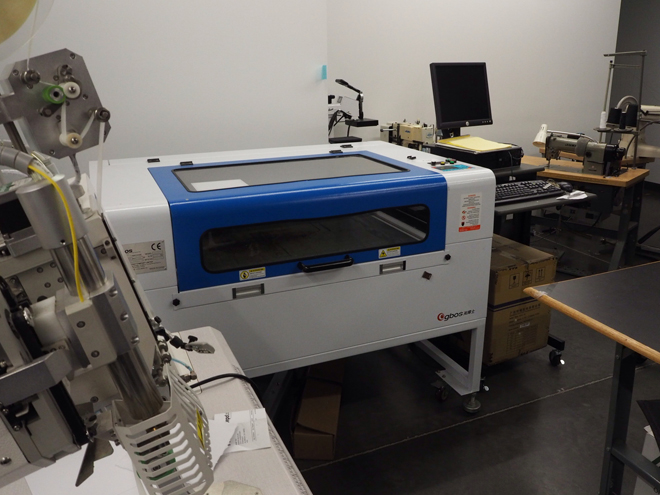

The Tinkering Room

AKA the play room, where Matt’s team get hands-on either by way of their spare sewing machines or the laser cutter or taping machine.

Bike Lockers

Like any good green establishment, TNF encourages their staff to pedal to work.

The Equipment Team Wing

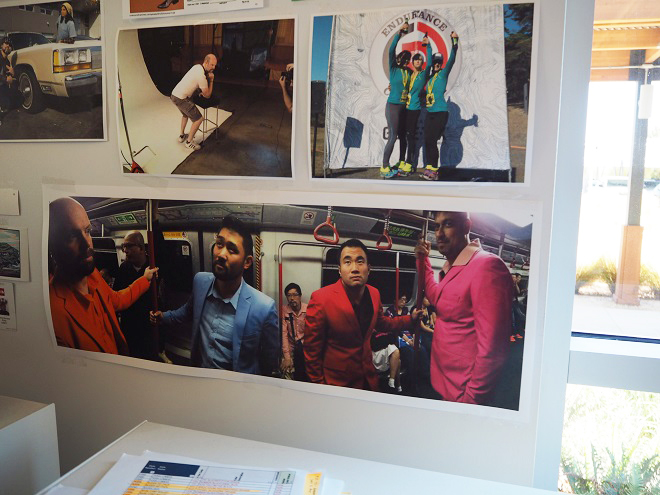

“And this is where we hang most of the time, ” Matt says, leading me into the wing of the EQ team, past a huddle of tents. Every desk is fanned with prototypes and models; action figures from Lego to Dragon Ball Z pose frozen across the edges of the dividers. On the back wall, a montage and testament to the group’s signature good fun and hilarity – The Wall of Shame – hangs in all its glory.

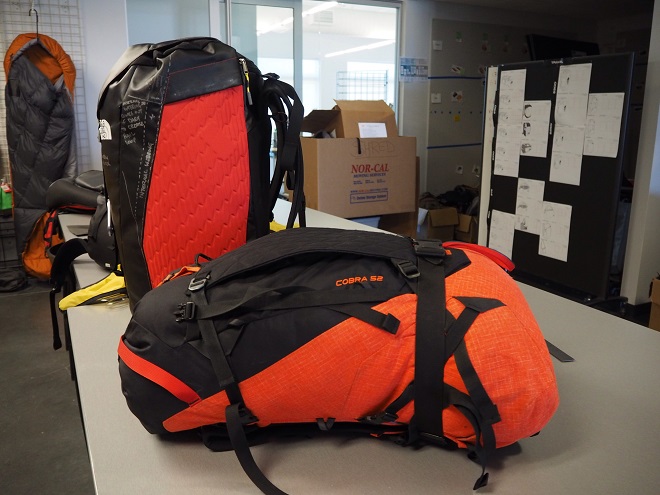

To my left, new Shadow and Cobra prototypes lie on a long wooden work bench, fresh chalk lines sketched down their flanks.

“We’re like five weeks in Fall 2017,” Matt tells me. Two years ahead of the curve. I ask how much product each of his team delivers: “Our designers work on as many as 20 to 30 styles each, per season.” That number leaves me a little gobsmacked; that’s a mega-ton of product, ranging from daypacks and technical packs, to sleeping bags, tents, gloves and accessories.

But the EQ team keep it super scheduled and agile (or how Matt likes to call it: a “well-choreographed ballet”) with a team culture that’s all about synergy – when a designer thinks a project is ‘bigger than them’ they can call in the team for a brainstorm or the group “pulls in” and another team member jumps on to help with the project.

““We’re like five weeks in Fall 2017,” Matt tells me. Two years ahead of the curve.“

Made up of designers, material coordinators, developers, color coordinators, product managers and a product director, they’re a close-knit bunch – who, I discovered funnily enough, boost morale by occasionally breaking out into all out in-office Nerf wars; one developer is even swapping out all the internal pieces with little CNC metal parts so the inside of his gun is “all like metal”.

“It’s kinda hardcore” laughs Hunter, one of EQ’s young designers.

(Top row, left to right – Matt Paduano, Hunter Nordhauser, Ezra Liang. Bottom row, left to right – Daniel Szekeresh, Ben Guthrie, Ryan Lee, Kellen Hennessey)

Matt calls the designers into a huddle to hang out, and they joke and jostle around and tell me the outdoors and “making awesome gear” is what binds them together. They get out nearly every weekend, hang out, test prototypes, and have what Matt likes to call a ‘user-centric’ culture.

“…when a designer thinks a project is ‘bigger than them’ they can call in the team for a brainstorm or the group “pulls in” and another team member jumps on to help with the project.“

“These guys are always out using product,” Matt says proudly. “Whether it’s winter or summer, whatever the activity: rock climbing, just general camping, fishing, abalone diving, snowboarding, skiing, there’s always somebody out using product.”

“Our designers work on as many as 20 to 30 styles each, per season.“

And on top of that, there’s the athlete team – TNF’s flock of super amazing humans, the ones you see hanging by fingertips from cliff edges or skiing down the gnarliest of uncharted powder. “Those guys are in here on a regular basis, a few times a year, in-house working on product. Like literally we’re designing product with Conrad Anker or Jimmy Chin or whomever it is. And that’s a great experience and these guys get out and do trips with the athletes as well so…we really kind of try to understand what their needs are, and solve their problems side by side.”

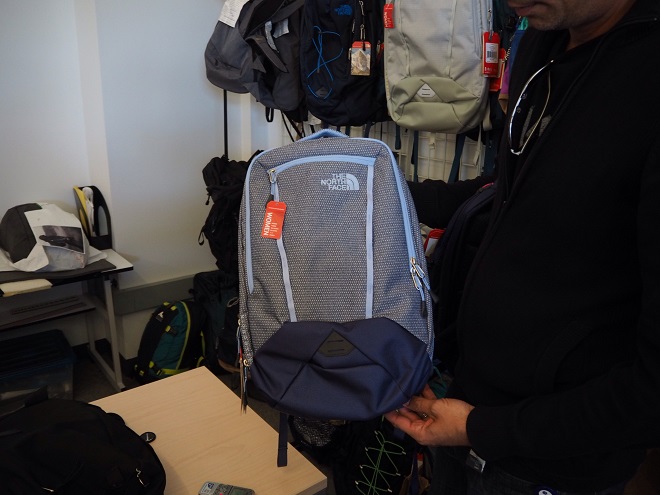

We jam a little on what’s in store for 16’/17’ and Matt leads me over to his desk, flanked by a wall of new samples. He holds up a cute purple daypack more geared to a new urban vibe, similar to what’s coming on Japan’s Purple Label.

“I think this is really going to help drive our aesthetic in the urban world; this one in particular we’ve designed for women.” Something the EQ team are really proud of. ” We started out doing some really in-depth studies about women’s gait, how they walk, different proportions, how the shoulder strap needs to have different flexibility…because women’s anatomy is so much different than a man’s. And so we started to experiment.”

The design team pinned life-size paper sheets to the walls, recruited ladies from the compound and traced their spines to compare S curves. There was such a range in height and actual curvature, and so they tried to address that by having more flexibility in the shoulder strap. They contoured the shoulder strap to be a different shape, slimmed down the profile (because ladies don’t want giant egg shapes on their backs), and addressed the amount of padding…but that’s just the beginning. The EQ team’s goal is to create the most comfortable carry system around, and they are still tweaking for Fall trans ’17.

“We started out doing some really in-depth studies about women’s gait, how they walk, different proportions, how the shoulder strap needs to have different flexibility…because women’s anatomy is so much different than a man’s.”

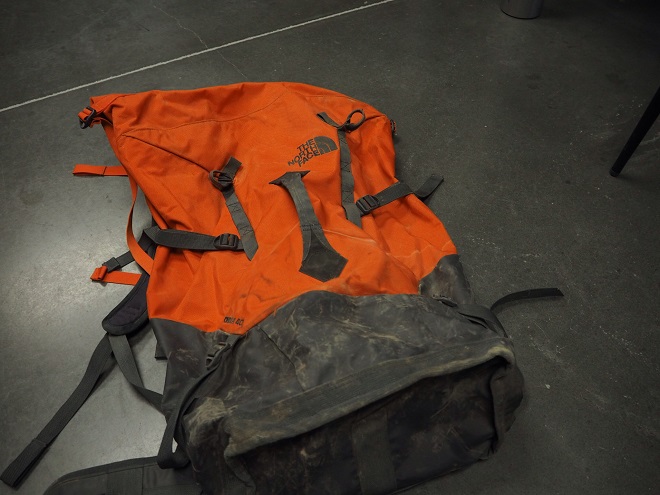

I’m proudly shown new sample after new sample: a new Shadow that looks amazing, another daypack that I can’t talk about (and hear of three top secret patents in the works – update: it was their new Access Pack!), and a new and improved Base Camp Duffel. Matt tells me about how they visited a college and just watched students load and unload their bags, analyzing their carry and tools and how they used the space in their packs – even holding strings of focus groups, just to nail the pocketing for school bags, their bread and butter.

“…we’re designing product with Conrad Anker or Jimmy Chin or whomever it is. And that’s a great experience and these guys get out and do trips with the athletes as well so…we really kind of try to understand what their needs are, and solve their problems side by side.”

It becomes apparent that not only is the EQ team consistently researching and tinkering and reimagining, but they’re also simplifying, going with cleaner patterns and designs – and it’s refreshing. For a brand juggernaut it’s difficult to take that care when churning out so much product – and honestly that was my concern coming in – but there’s an awesome vibe in the room, an energy, that is fed off of each other.

“…not only is the EQ team consistently researching and tinkering and reimagining, but they’re also simplifying, going with cleaner patterns and designs – and it’s refreshing.“

The EQ team, the self-proclaimed ‘ragtag bunch’, love what they do and are “the end user”, loving the outdoors as much as their legions of TNF faithfuls. Plus they work in an environment (and a kick-ass facility) that lets them have fun whilst doing it. And these guys are designing two years ahead of the curve at breakneck quantities with a smile on their faces!

That’s something for all of us to learn from.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews